EWM CF133: Configuring Auto Packaging (Pick-HU) with WOCR during Outbound Process for EWM Managed Warehouse in SAP

In this blog, we are only going to cover configuration related to Auto Packaging and not the WOCR and Packaging Specification.

To set up the initial WOCR configuration, Please check out this BLOG.

To set up the Initial Packaging Specification configuration, Please check out this BLOG.

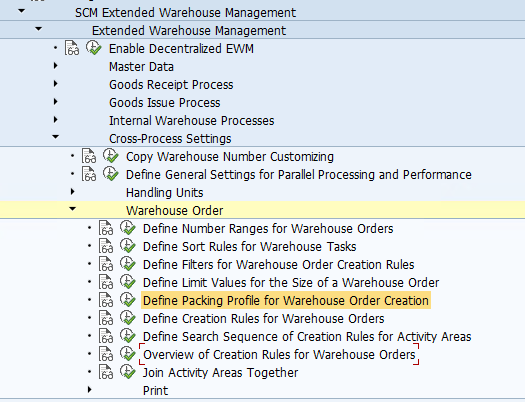

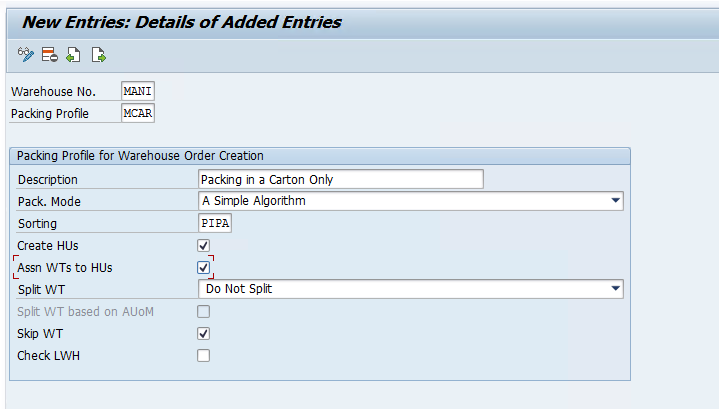

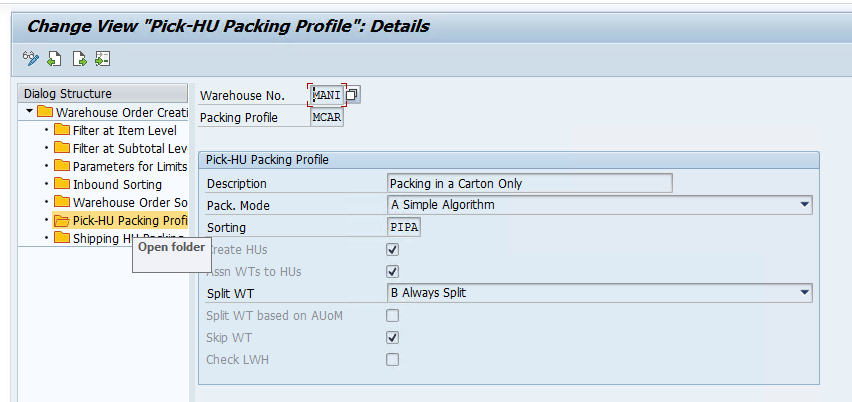

Step 1: Define the Packing Profile for WOCR

We have created a Packing Profile MCAR which stands for packing of Products in Cartons. This Packing Profile will be used in the Packaging Specification for the Product.

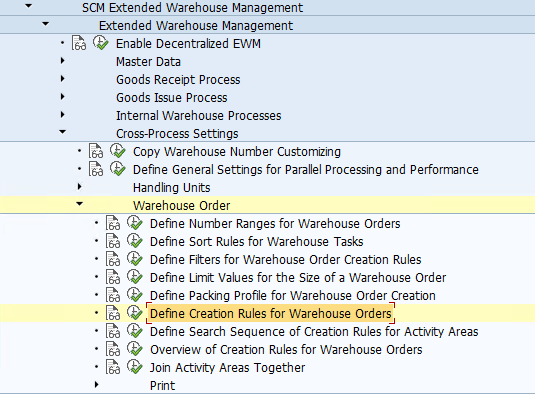

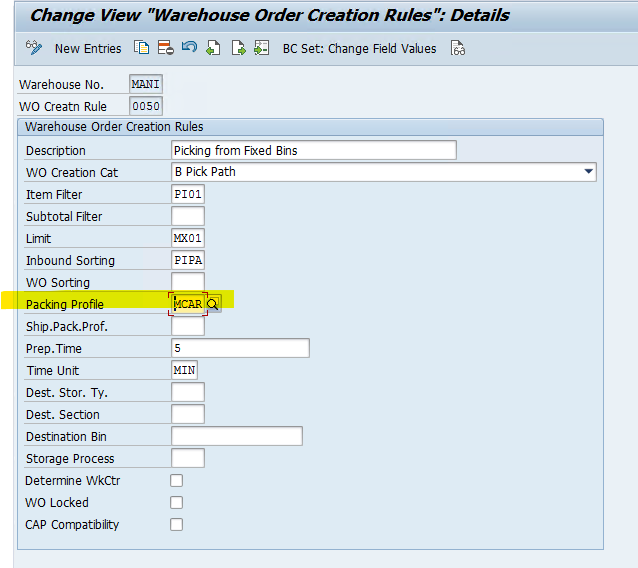

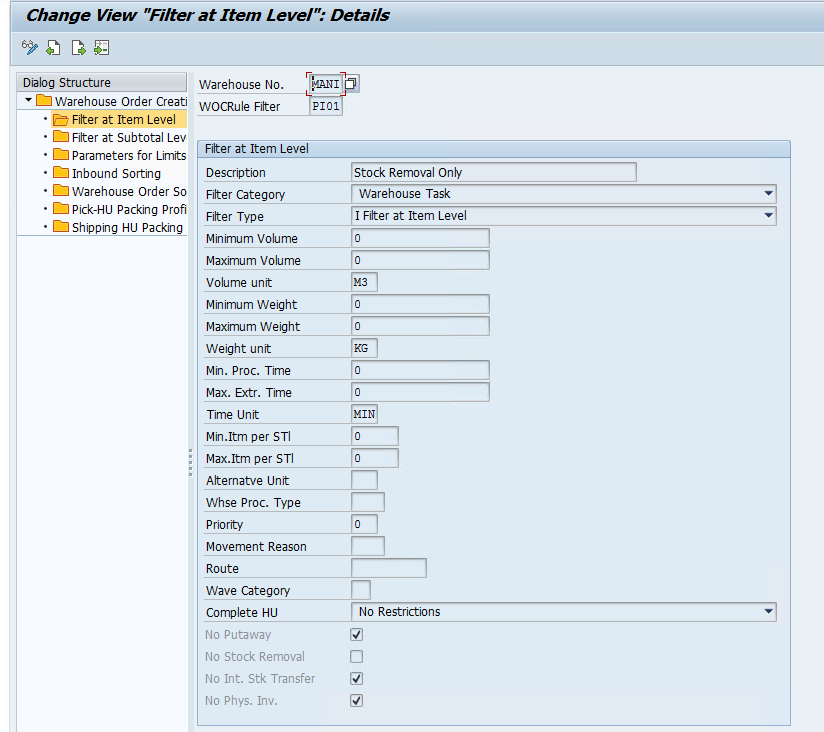

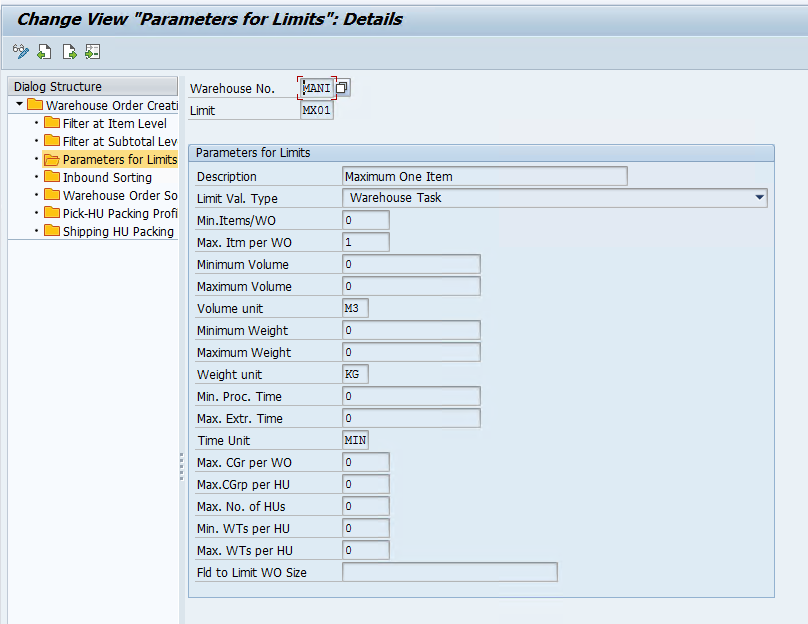

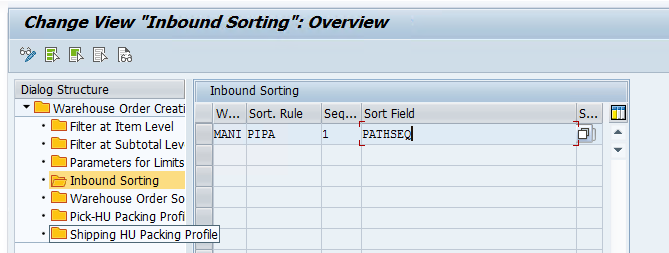

Step 2: Maintain the Packing Profile in the Creation Rule for Warehouse Orders.

Since I have created WOCR 0050 for this Blog I will give an overview of the WOCR.

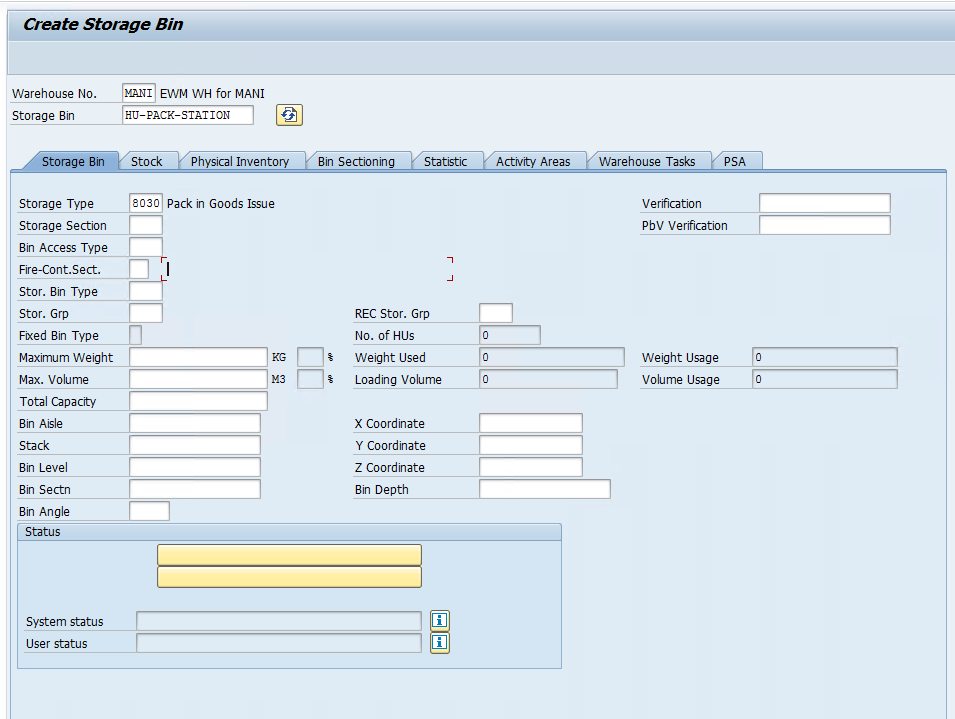

Step 3: Maintain a Storage Bin for the HU Packing.

We need to create a Storage Bin in a Storage type where the Packing of HU will take place, make sure you create this Bin under a Storage type that allows HUs, we are using standard Storage Type 8030 — Pack in Goods Issue. Tcode: /SCWM/LS01

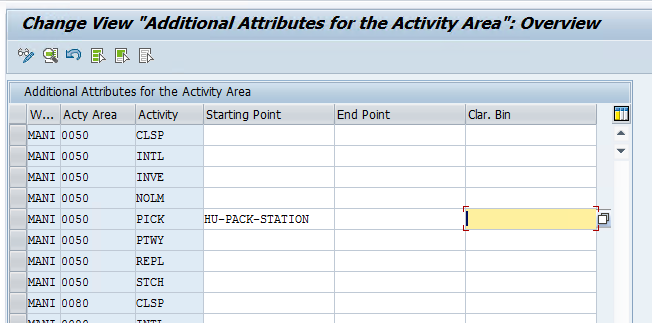

Now assign this to the activity area for this we created our WOCR and activated auto packaging through WOCR. /SCWM/SEBA

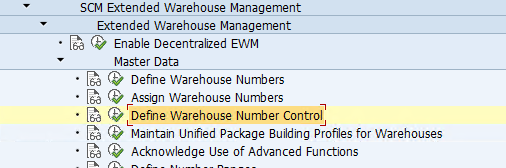

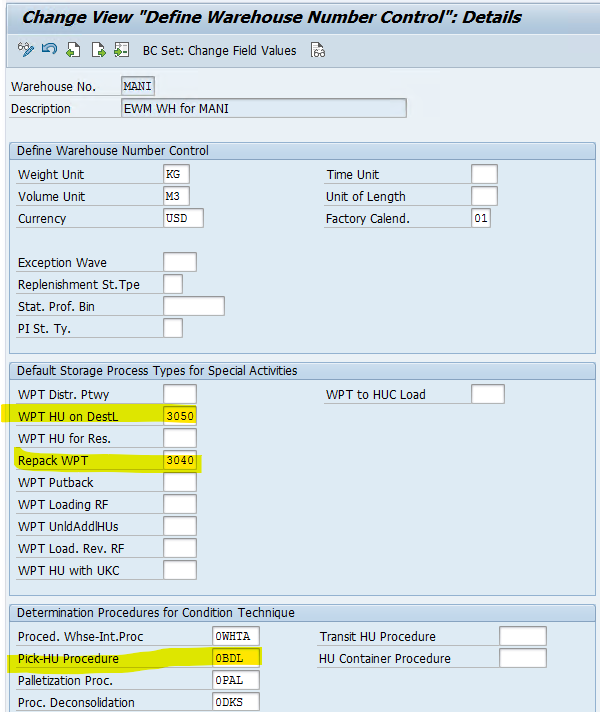

Step 4: Now we need to maintain standard WPTs at the Warehouse level to successfully create Pick-HUs

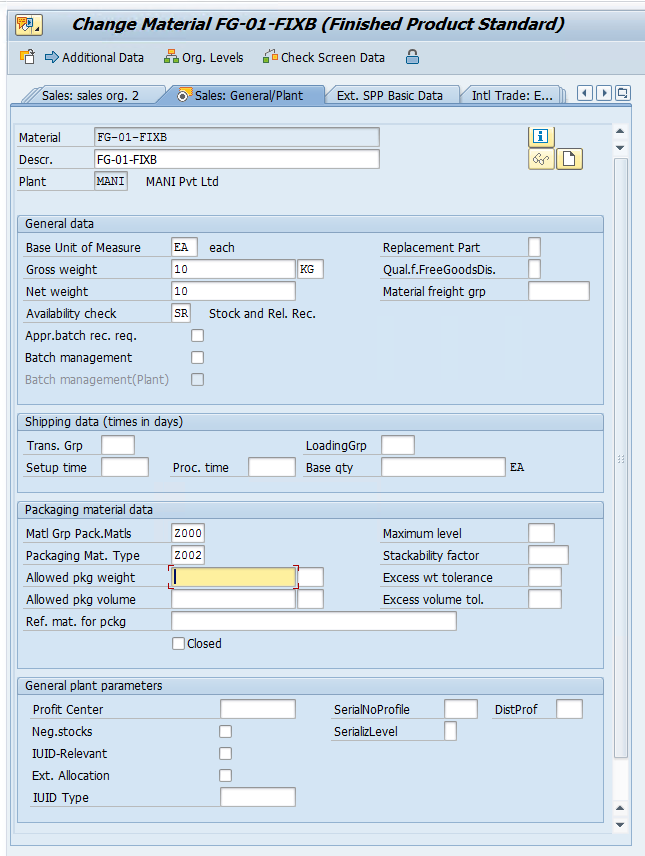

Step 5: We need to maintain the master data for our Product/Material Master Data to pack the product during warehouse order creation. We also need to maintain the Packspec.

Maintain Packaging Material Type in the Material Master.

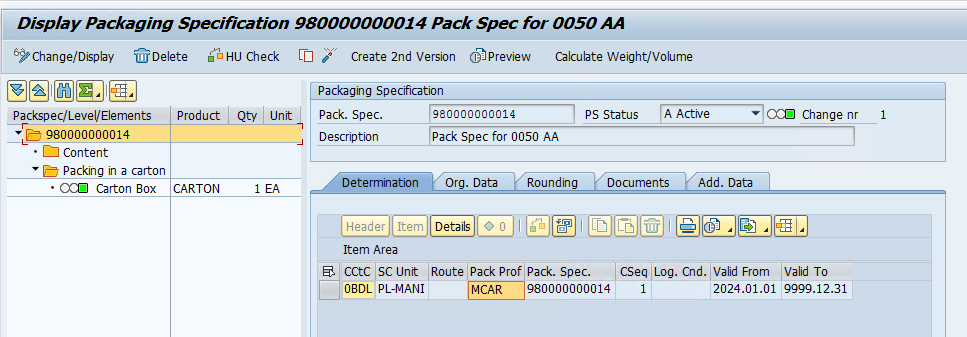

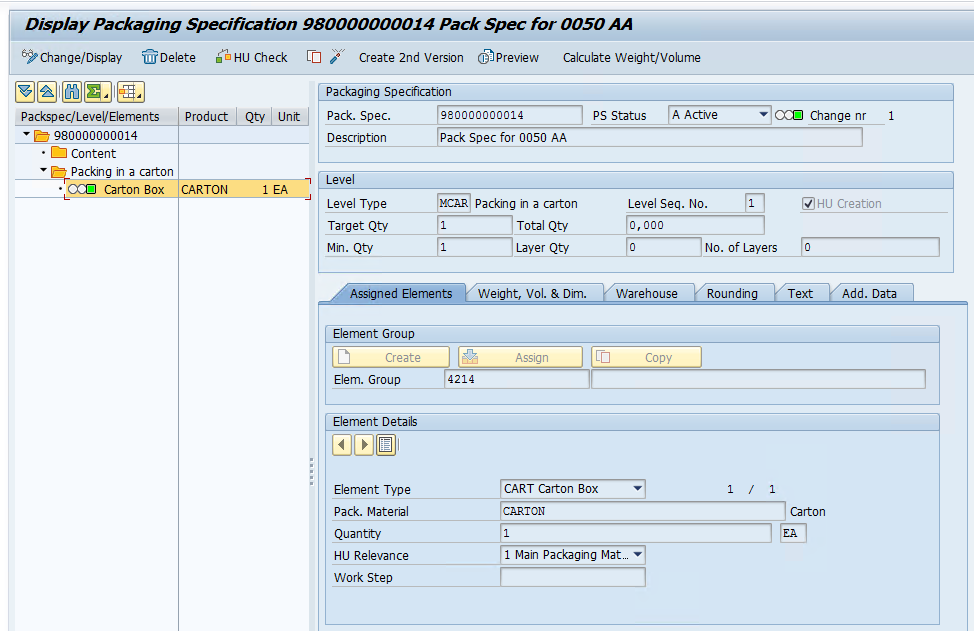

/SCWM/PAKSPEC Create a packaging specification

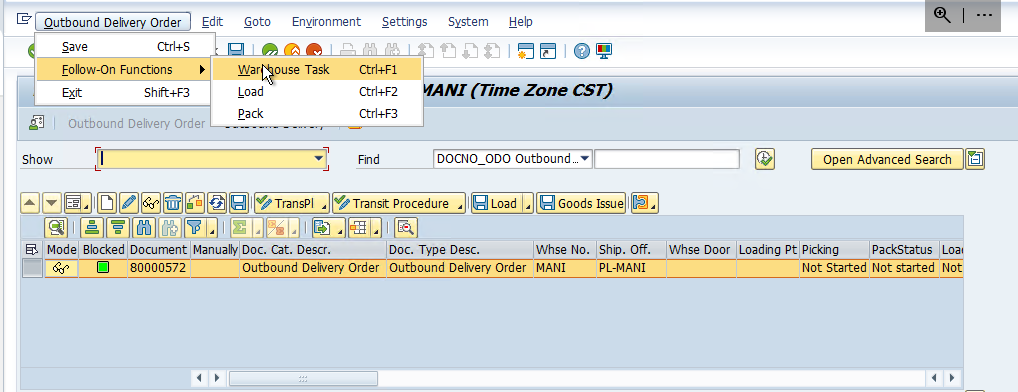

Now we can test our configuration, first, we need to create an OBD in the S4 system and make sure it gets distributed to the EWM system.

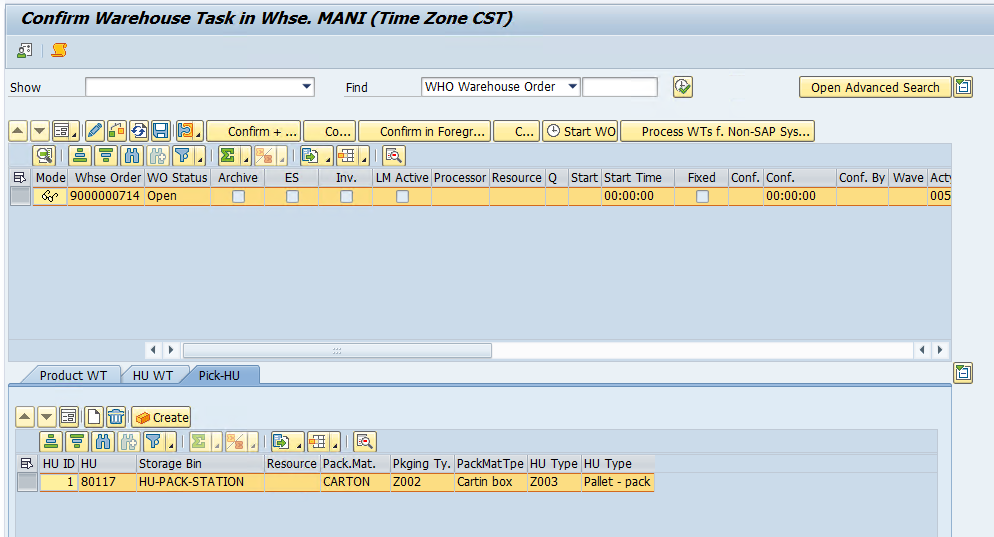

Create a Picking WT and use Tcode /SCWM/TO_CONF to confirm the open WO.

As can be seen in the below Screenshot, Pick-HU is created automatically.

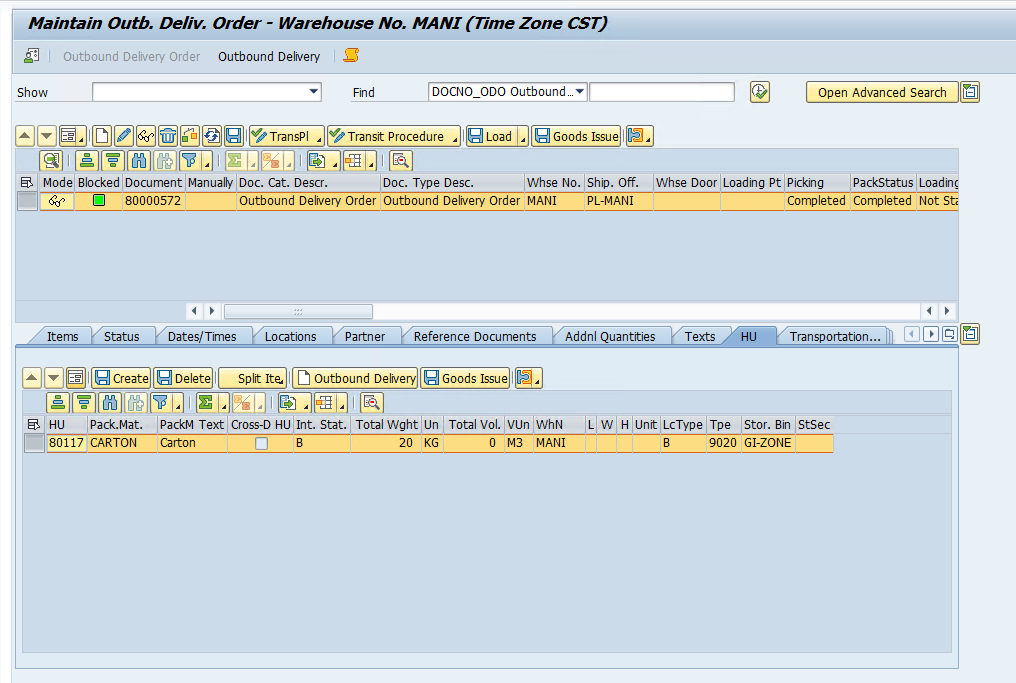

Once we confirm this WO, the HU will get created and moved to the GI ZONE for PGI.

Now we can complete the PGI.