Configuration and Business process steps

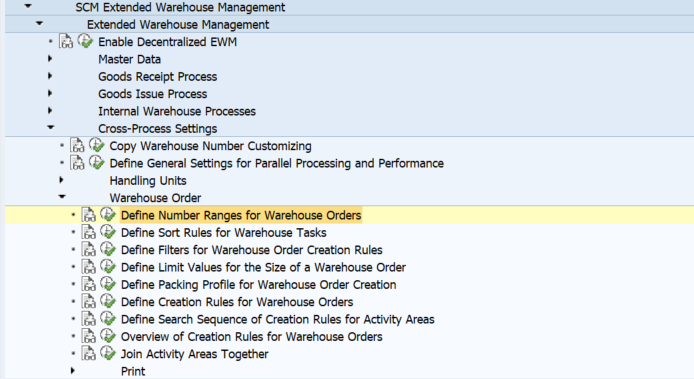

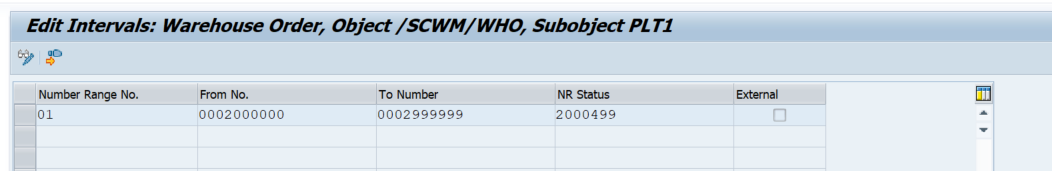

Create a Number range for WO and assign it to your WH number

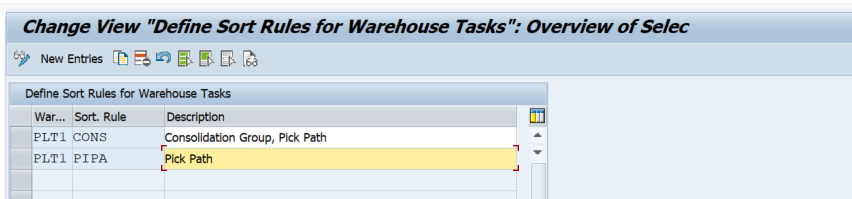

2. Create a Sort Rule for WTs

You can define sort rules for warehouse tasks. You enter the criteria for creating the list of warehouse tasks within a warehouse order during the warehouse order creation.

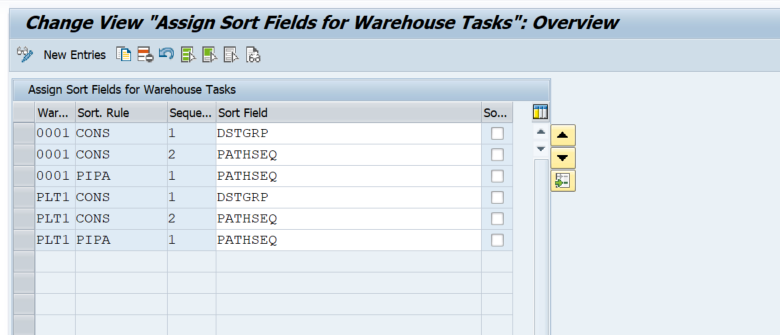

After you’ve defined the sort rule, you select the corresponding sort criteria.

Within warehouse order creation, you can use the sort rules defined in this way at three points during processing:

- Sorting all warehouse tasks at the start of warehouse order creation (inbound sorting), as soon as warehouse order creation processes a sort rule

- Sorting all warehouse tasks that are part of a warehouse order, at the end of warehouse order creation

- Sorting all warehouse tasks during packing for determination of pick-handling units (for example, by weight)

Standard Sort Role:

Consolidation group: Consolidation group, pick path

Pick path: Destination storage type, destination storage section, destination storage bin, pick path

Pick & Pack: Destination storage type, destination storage section, destination storage bin, pick path

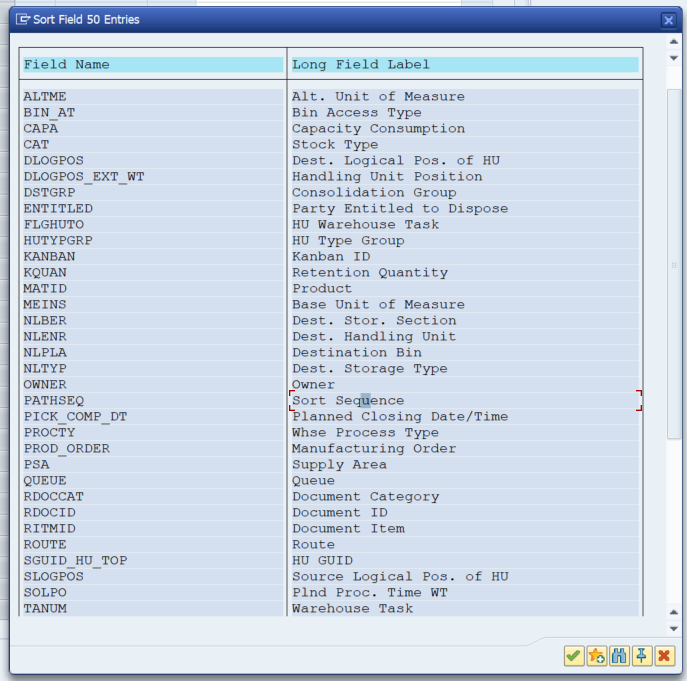

Define Sort fields

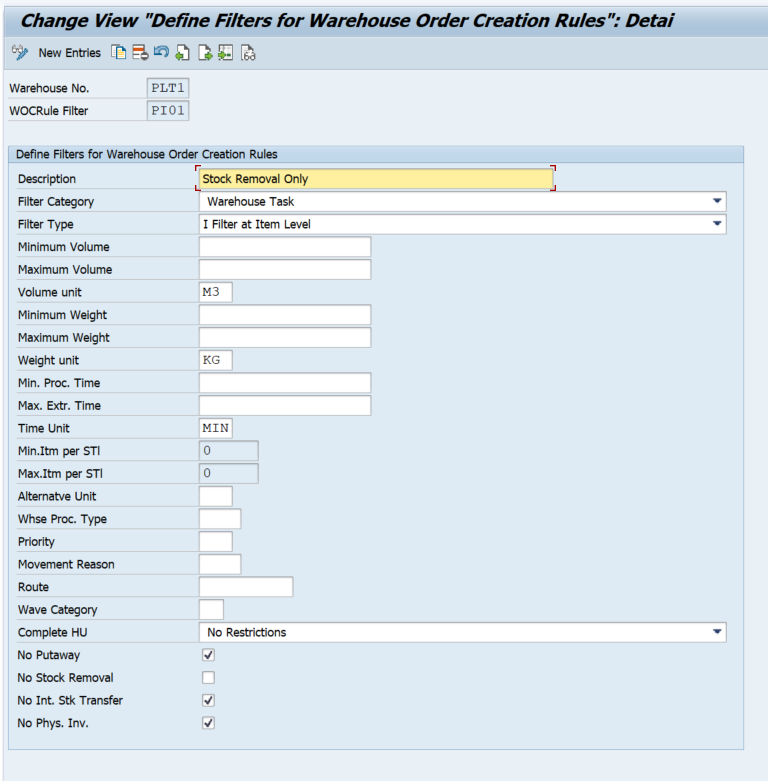

3. Define Filters for WOCR

Some possible filter criteria for the item filter.

- Minimum volume to maximum volume

- Minimum weight to maximum weight

- Minimum processing time to maximum processing time

- Alternative unit of measure

- Warehouse process category

- Route

- Wave category

- Full pallet withdrawal

Some possible filter criteria for the Subtotal filter.

- Minimum volume to maximum volume

- Minimum weight to maximum weight

- Minimum processing time to maximum processing time

- Minimum number of items to maximum number of items

We need to define consolidation groups if we need to use the subtotal filter.

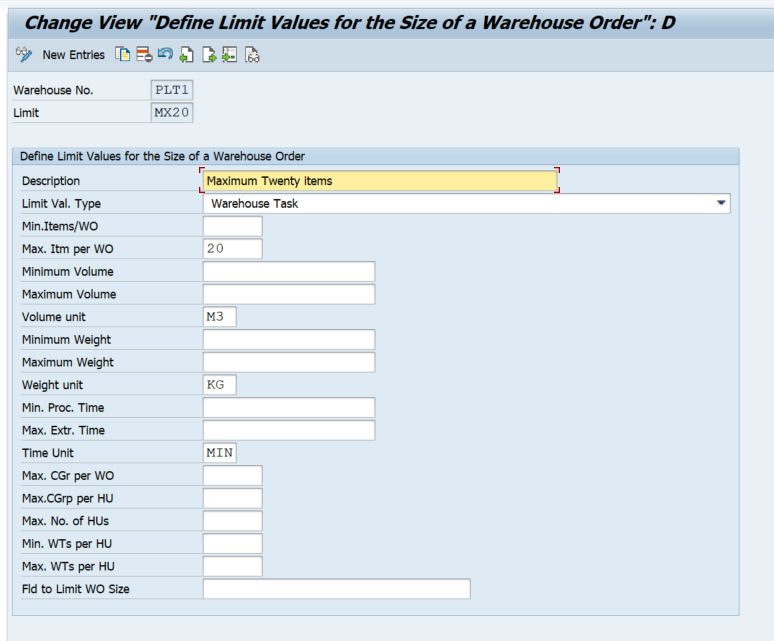

4. Define Limit Values for the Size of a Warehouse Order

You can define the following values for the minimum and maximum limits of the warehouse order:

- Maximum number of items in each warehouse order

- Maximum weight of the warehouse order

- Maximum volume of the warehouse order

- Maximum processing time of the warehouse order

- Maximum number of different consolidation groups in a warehouse order

- Minimum number of items in each warehouse order

- Minimum weight of the warehouse order

- Minimum volume of the warehouse order

- Minimum processing time of the warehouse order

You can define the following values as minimum and maximum limits of the warehouse order:

- Maximum number of different consolidation groups in a pick-handling unit (HU) for the warehouse order

- Maximum number of pick-HUs

- Maximum number of items for each HU

- Minimum number of items for each HU

- You can specify a warehouse task field to limit the warehouse order size

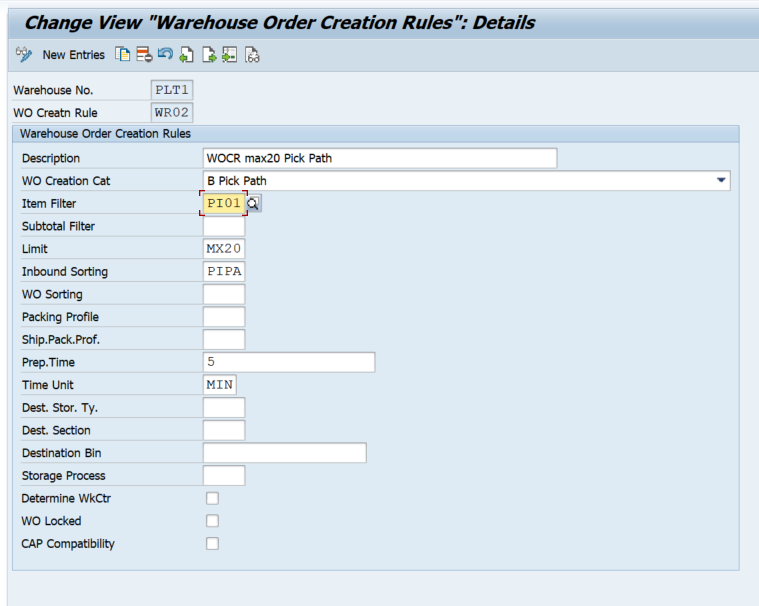

5. Define Creation Rules for Warehouse Orders

Standard settings

In the standard system, there are predefined warehouse order creation rules for warehouse number 0001.

We recommend that you avoid using the following abbreviations to identify warehouse order creation rules since we have already assigned them internally for existing warehouse order creation rules. This ensures that the identification you define for a warehouse order creation rule is unique.

- DEF: Standard rule

- UNDE: Remainder rule

- MFS: Warehouse order rule for warehouse tasks that are relevant to the material flow system

Activities

Define the warehouse order creation rules necessary for your warehouse.

- Choose the rule category.

Warehouse order creation processes the various categories in different ways. - Choose an item filter that you have defined under Define Filters for Warehouse Order Creation Rules. Warehouse order creation takes these filters into account for the current warehouse order creation rule.

- Choose a subtotal filter that you have defined under Define Filters for Warehouse Order Creation Rules. Warehouse order creation takes these filters into account for the current warehouse order creation rule. It uses the subtotal filter for consolidation group rules and compares the values defined here with the corresponding subtotals at consolidation group level.

- Choose the limit for the size of a warehouse order, which you have defined under Define Limit Values for the Size of a Warehouse Order.

- Choose one of the sort sequences defined under Define Sort Rules for Warehouse Tasks as the inbound sorting. Extended Warehouse Management (EWM) uses this sorting at the beginning of warehouse order creation on the basis of the current warehouse order creation rule.

- Choose one of the sort sequences defined under Define Sort Rules for Warehouse Tasks as the Sorting Rules Within a Warehouse Order.

- Choose Packing Profile if you want to use a specific packing profile you defined in Define Packing Profile for Warehouse Order Creation in order to define the required pick-handling units.

- Choose Ship.Pack.Prof. if you want to use a specific profile you defined in Define Packing Profile for Warehouse Order Creation. At this point, warehouse order creation uses the packing profile to determine the shipping handling units.

- Enter the destination storage type, destination storage section, and destination storage bin to specify the work center to which the WTs, which have been grouped using the current warehouse order creation rule, should be taken. If you enter a packing station here, note the links with work center determination and the storage process.

- If you define a creation rule for the creation category Consolidation Group or Pick Path, you have the option to set Work Center Determination, so that warehouse order creation determines the work center with the help of Customizing.

- Enter the storage process that you defined in Process-Oriented Storage Control. For picking, you can enter a packing station as the destination for a WT, by entering the destination storage type, destination storage section, and destination storage bin.

- If you want to generate warehouse orders with the status Locked, set the WO locked indicator. This enables you to create warehouse orders in the productive environment with new rules, and to view the result before processing.

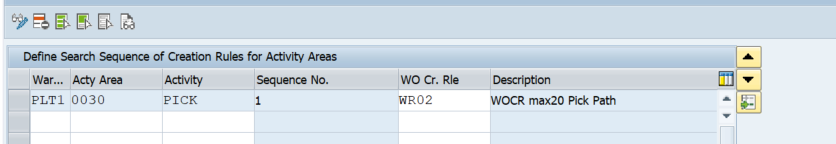

6. Define the Search Sequence of Creation Rules for Activity Areas

In this Customizing activity, you define the search sequence of warehouse order creation rules for activity areas.

You can assign one or more warehouse order creation rules to each defined activity area. These rules are processed during warehouse order creation for each activity area, according to the sequence defined.

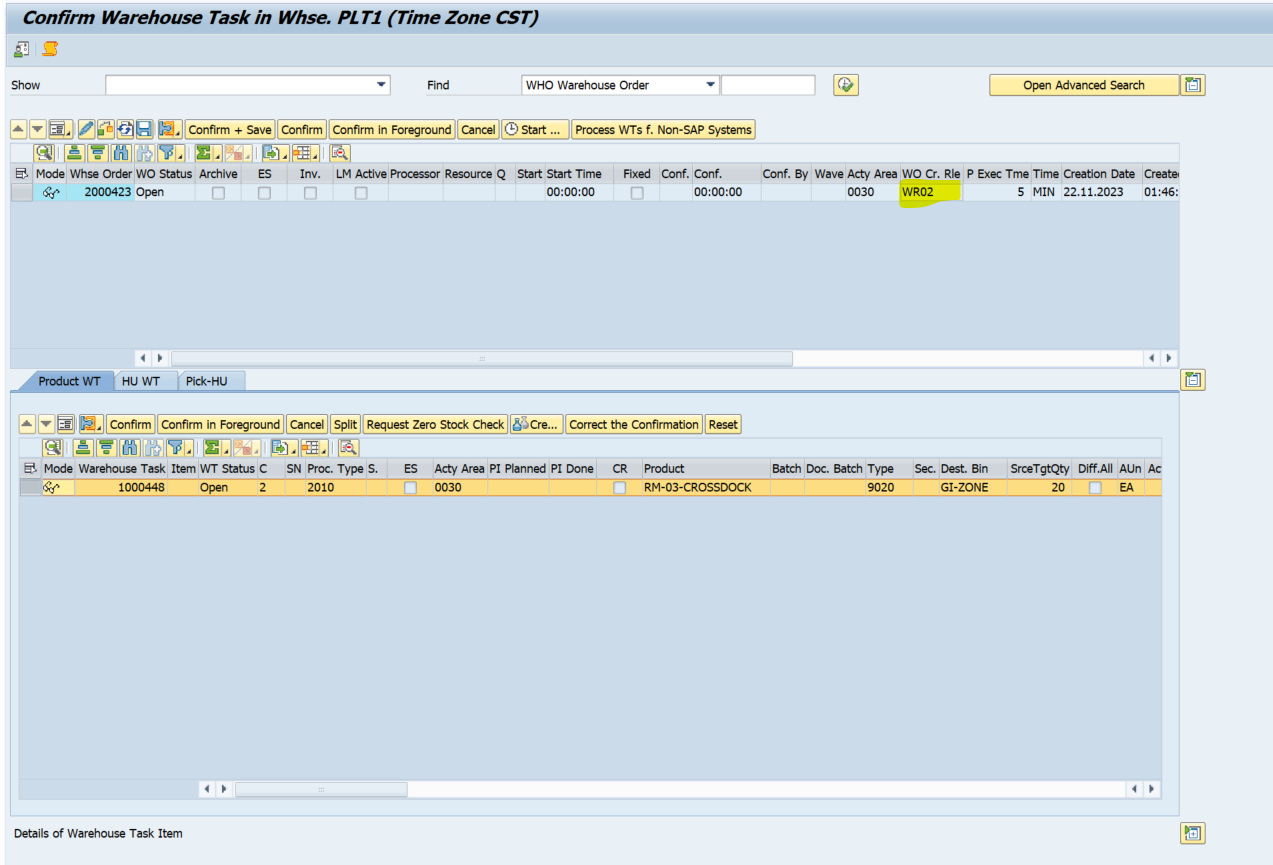

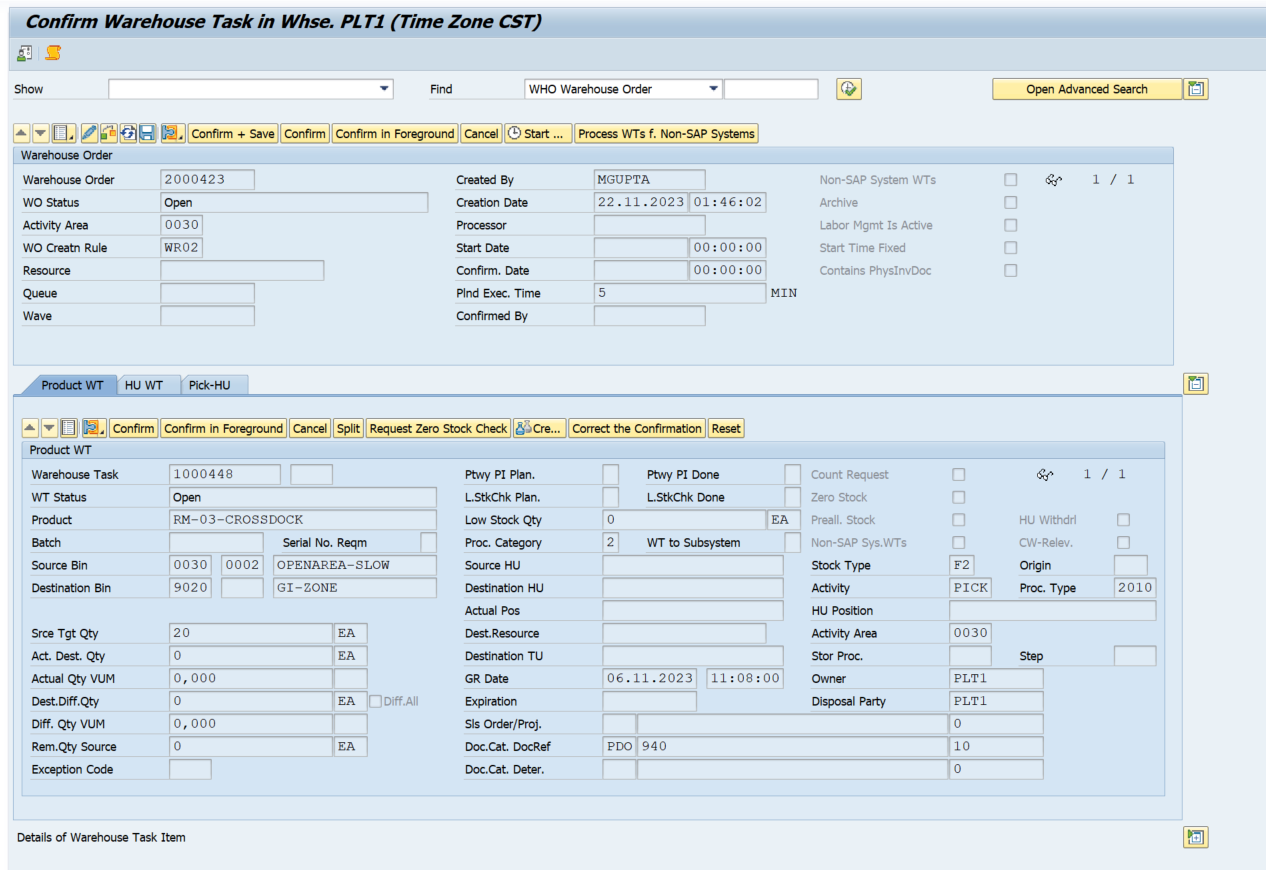

Once these settings are maintained, create a WT against an outbound delivery order and the WT will be assigned to the WO based on our WOCR.