Here we are going to discuss a very basic business scenario related to QM and EWM integration which is done through Storage Control (POSC).

Please check this Blog to configure the QM-EWM integration.

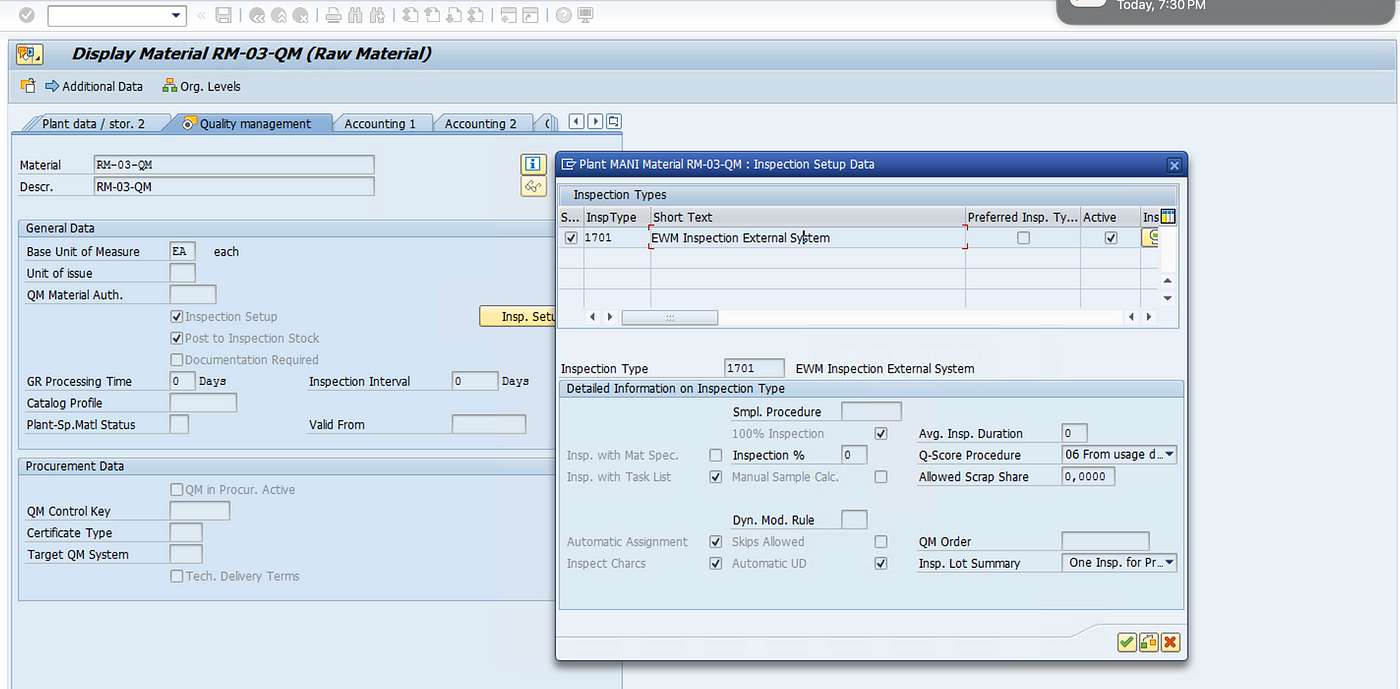

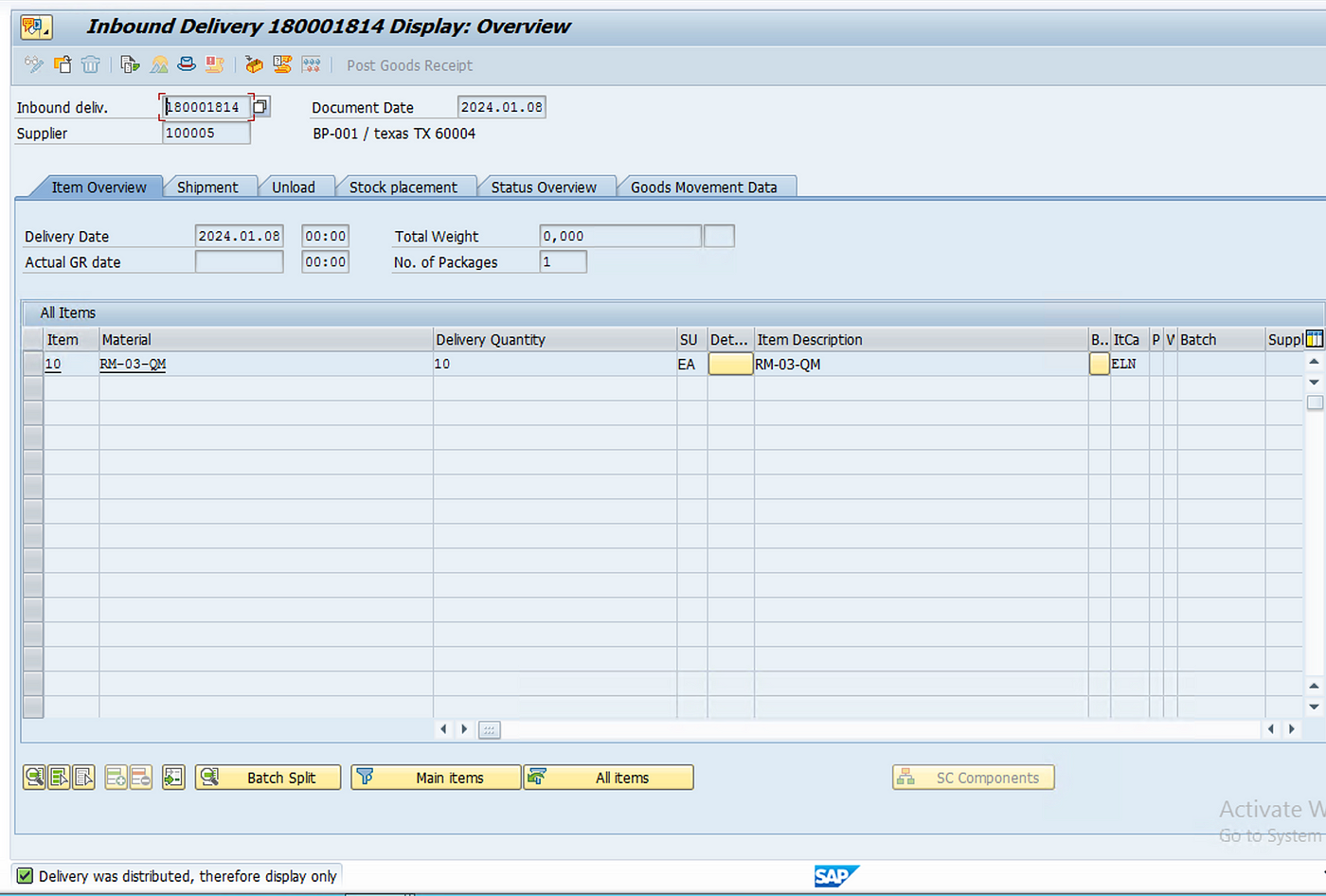

Step 1: Create a PO with Material which already has QM view maintained and create the Inbound Delivery against the PO.

we have also packed the stock in a HU while creating Inbound Delivery in S4.

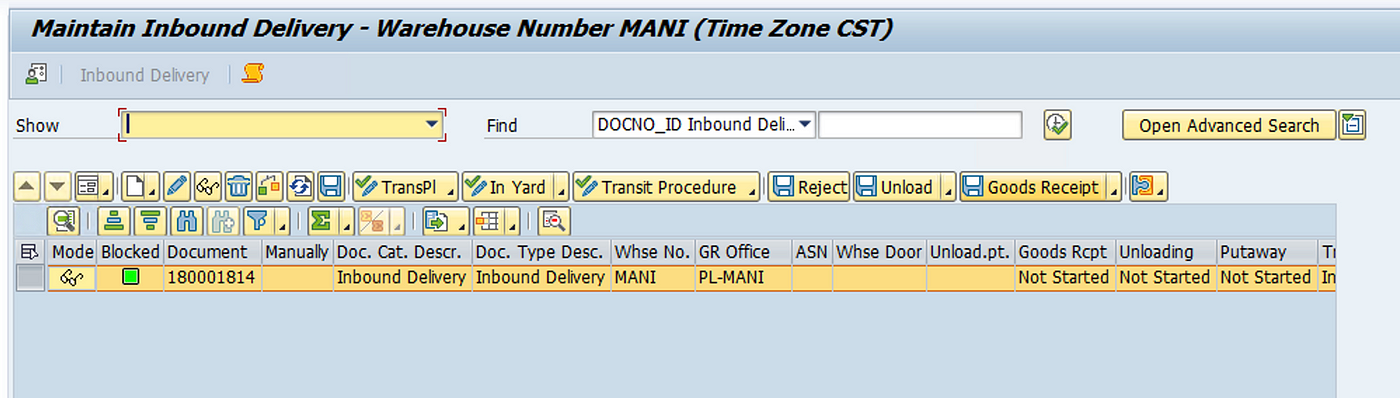

Step 2: Click on Goods Receipt button to carry out GR in /SCWM/PRDI

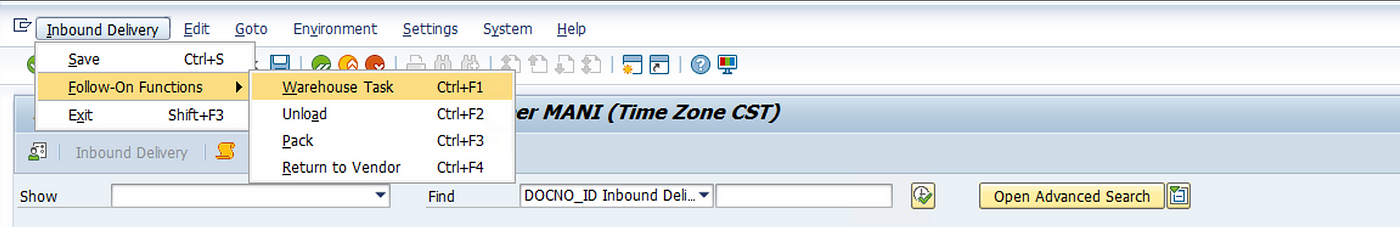

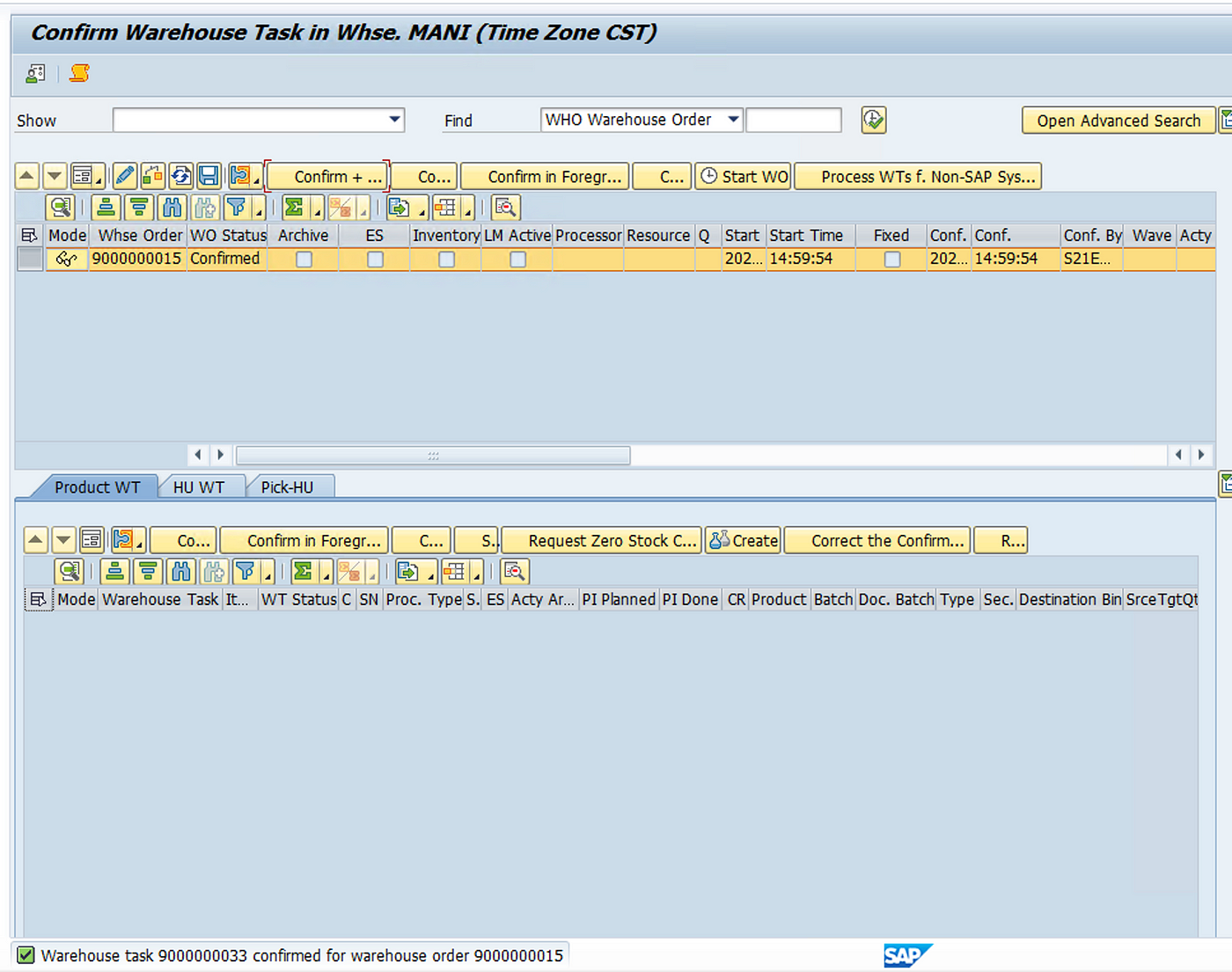

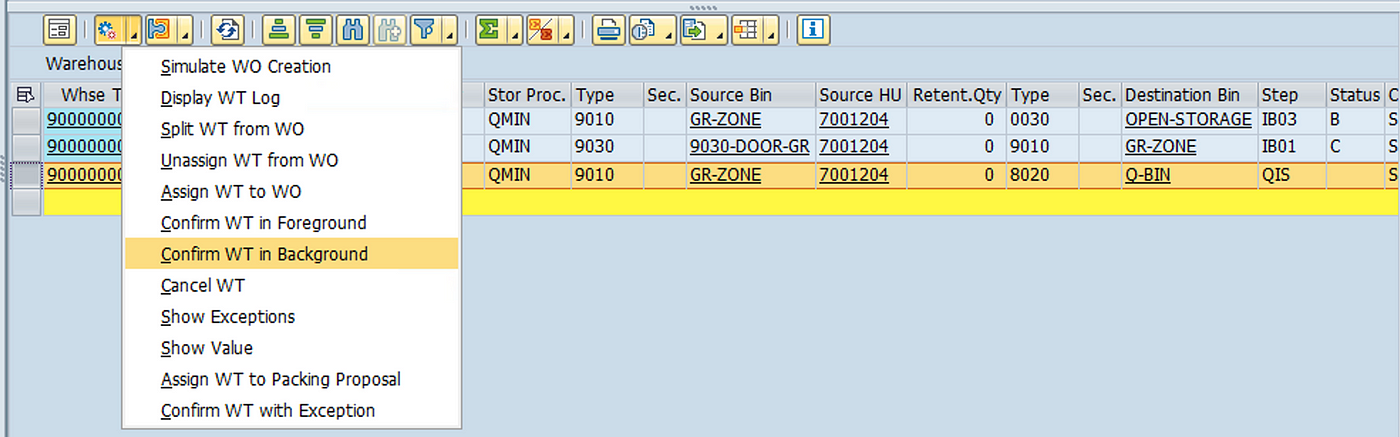

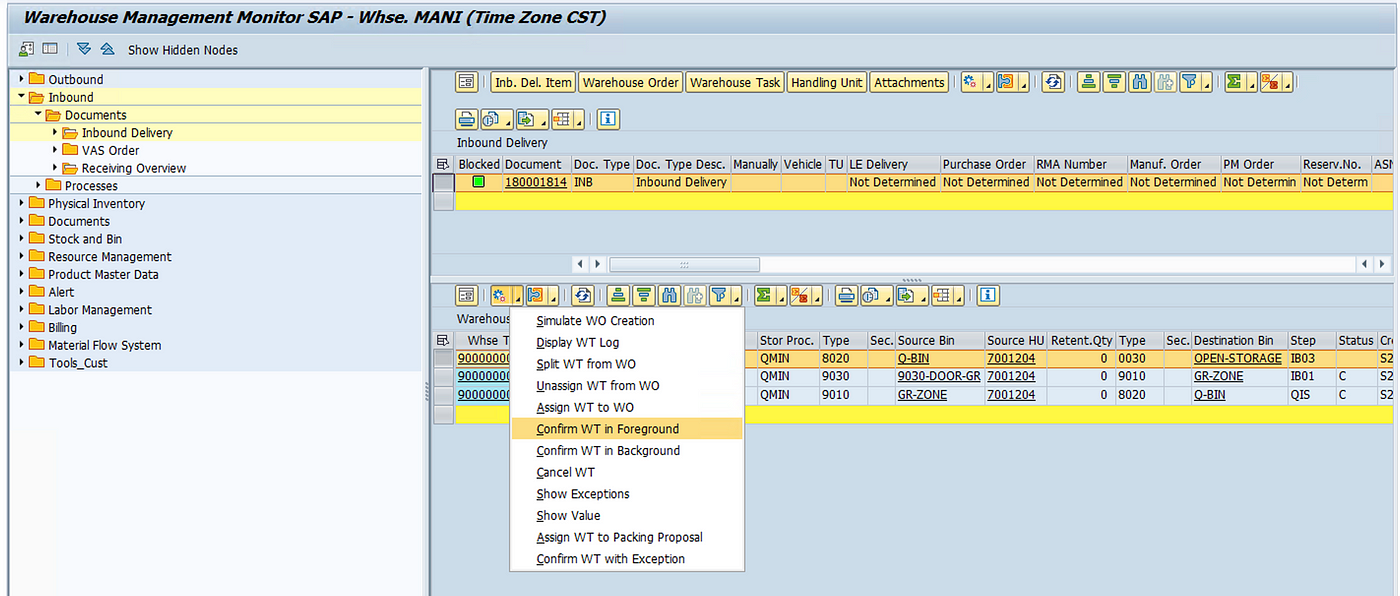

Step 3: Create WT and the system will create 2 more WTs based on POSC, and confirm the first WT.

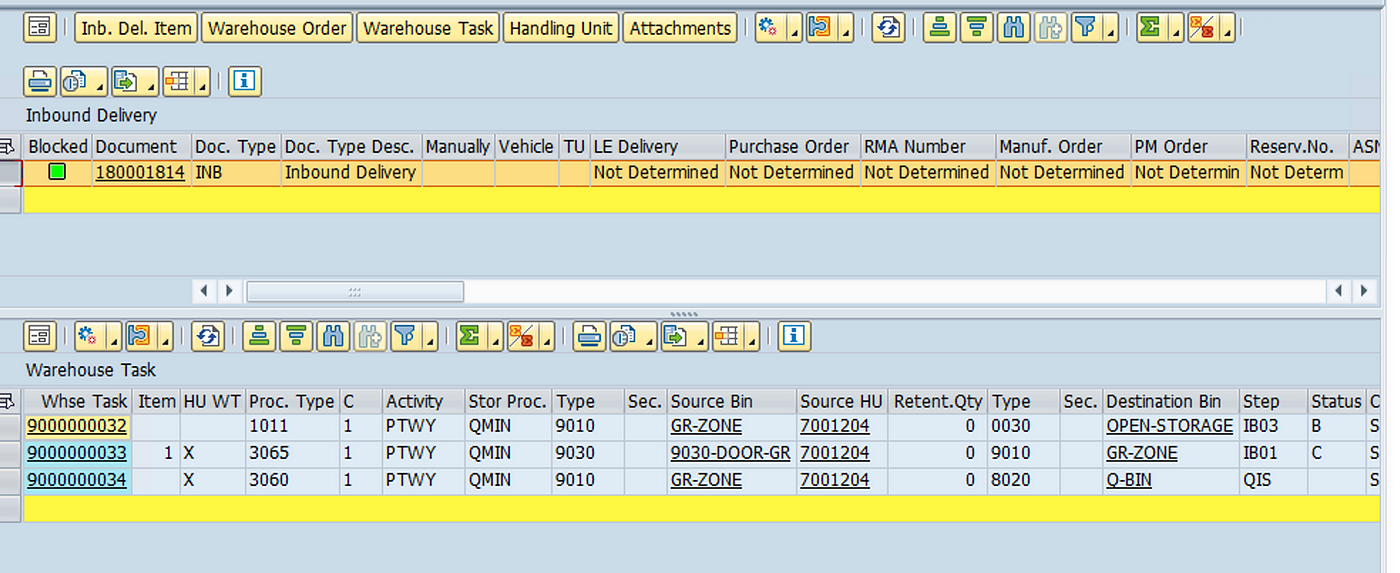

Check the Monitor to see the WTs created by system.

The first WT which was confirmed moved the stock from 9030 Door to 9010 GR-Zone and the next WT was activated which will move the stock to the 8020 Q-Bin so that quality inspection lot is created.

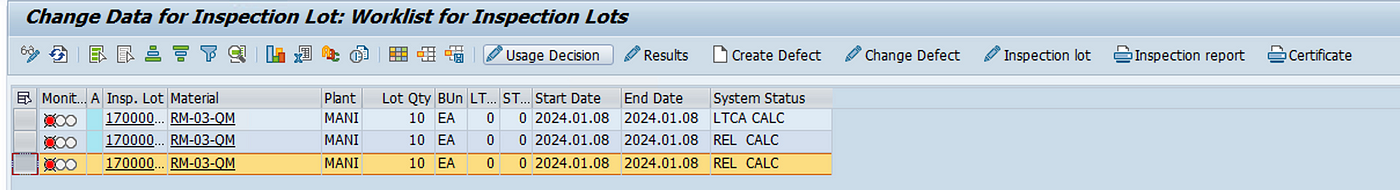

Step 4: Once stock is moved to quality inspection work center, we can execute the UD for out inspection through QA32 in S4.

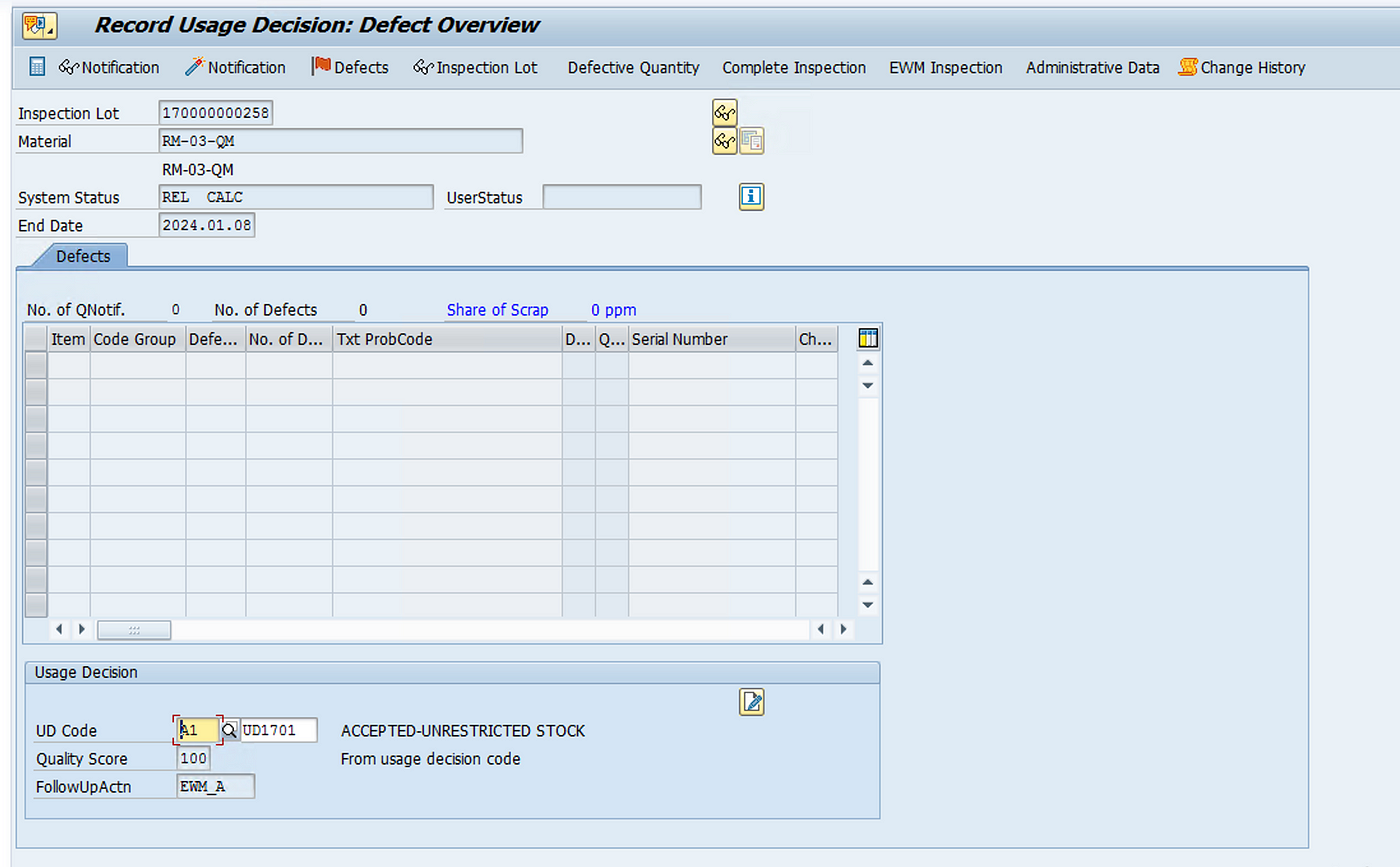

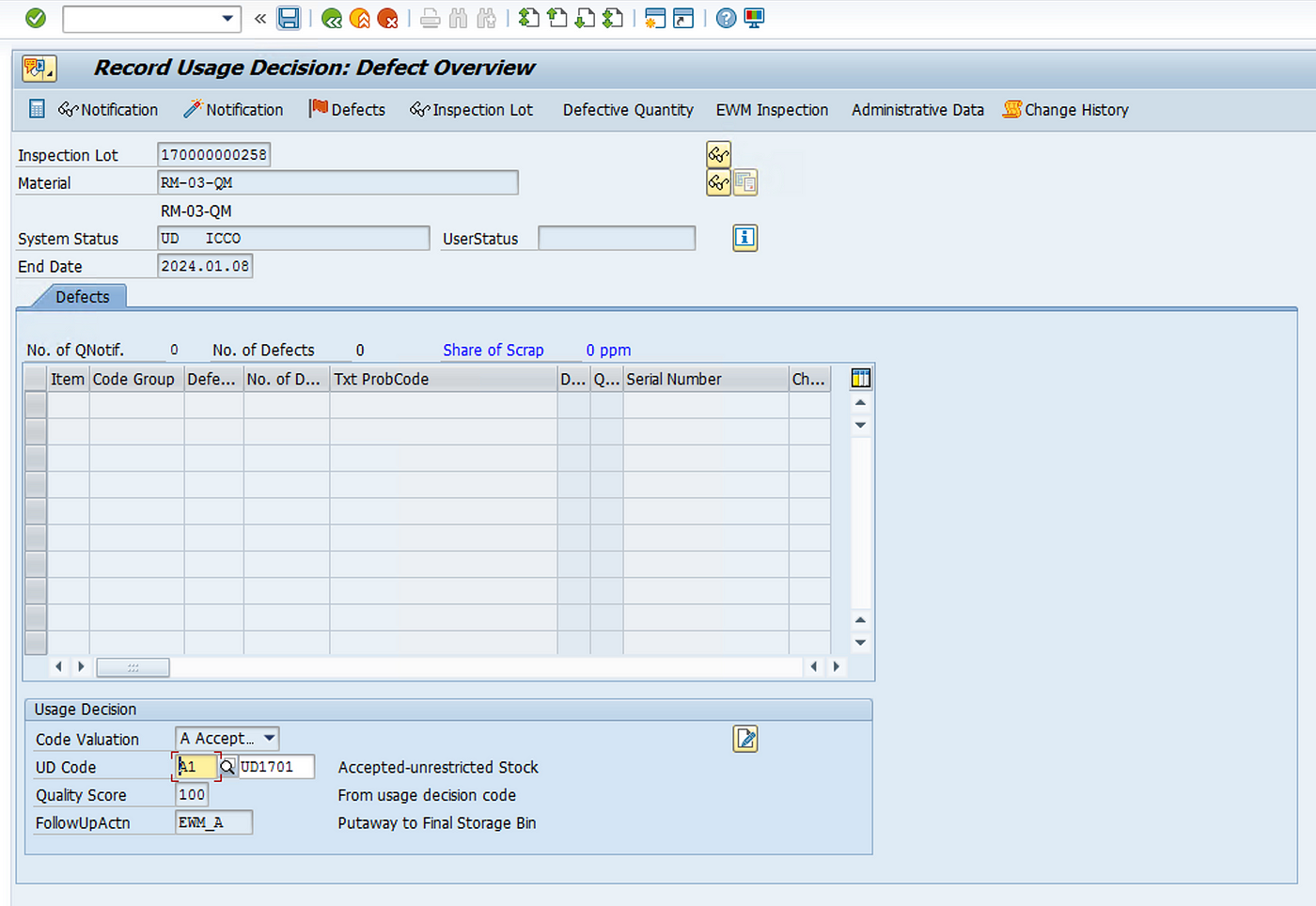

Click on Usage Decision to complete the UD for Inspection Lot

Once UD code is selected, click on EWM Inspection button on top ribbon.

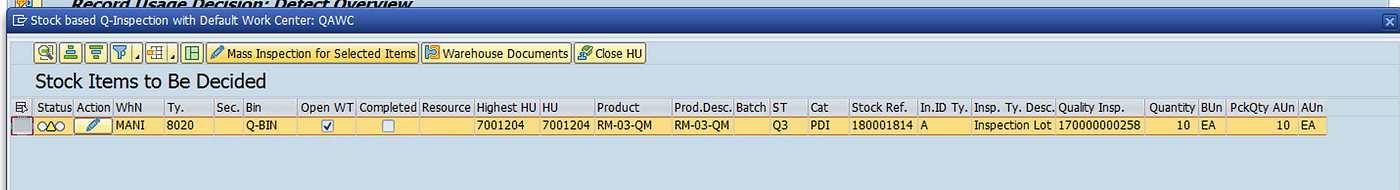

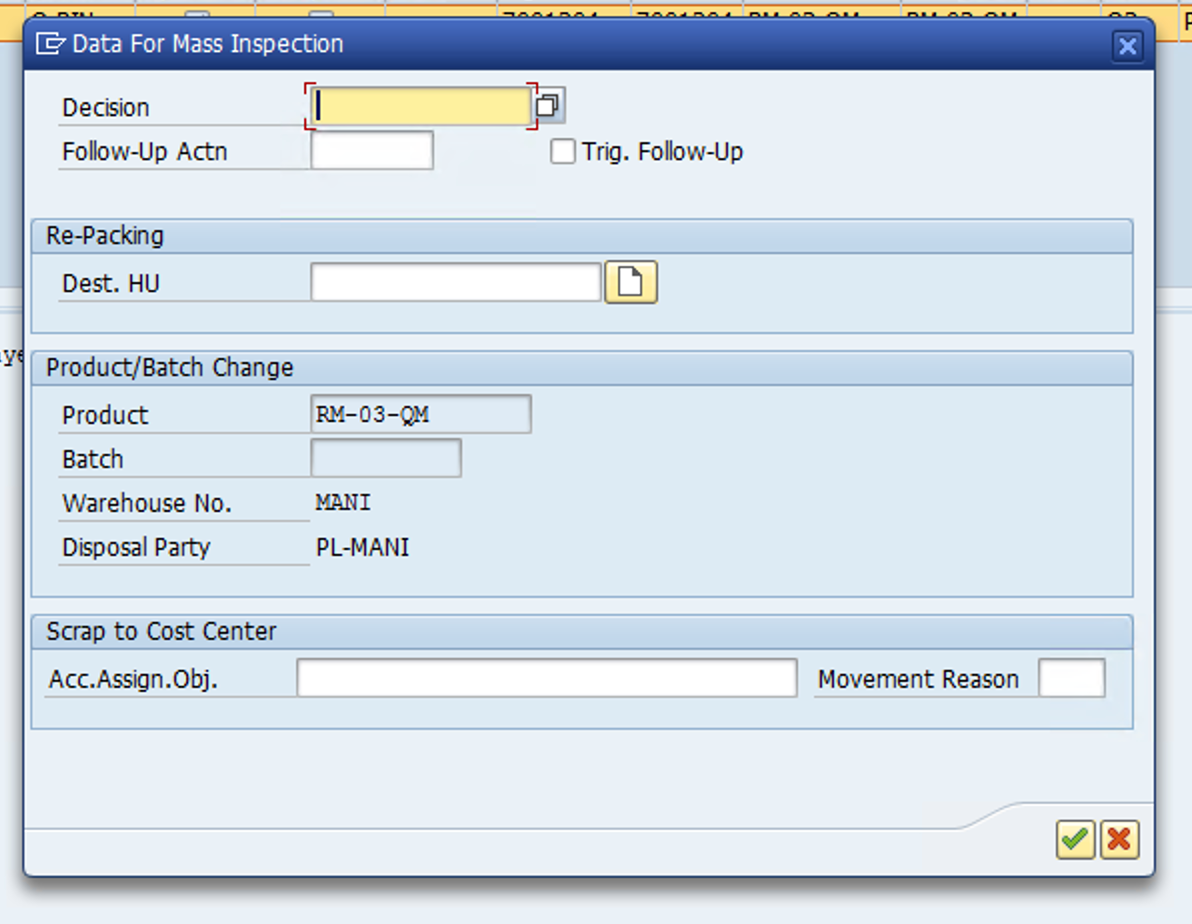

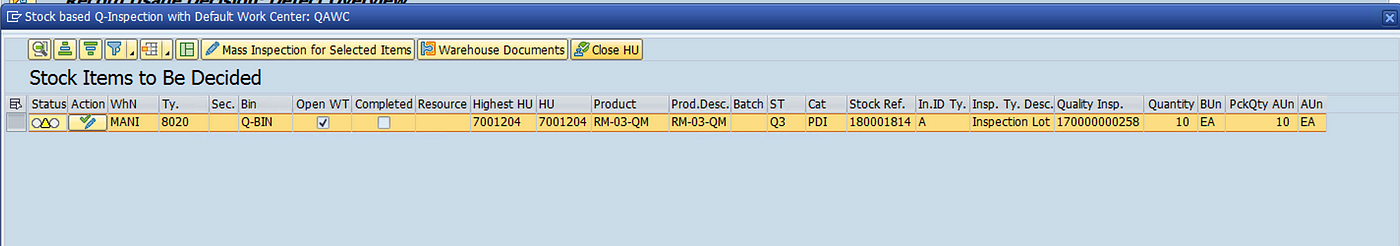

Select the line item and click on Mass Inspection button and select the correct decision for EWM Stock.

Select the Decision and follow up Action and press enter then click on Close HU button on top of the dialog box.

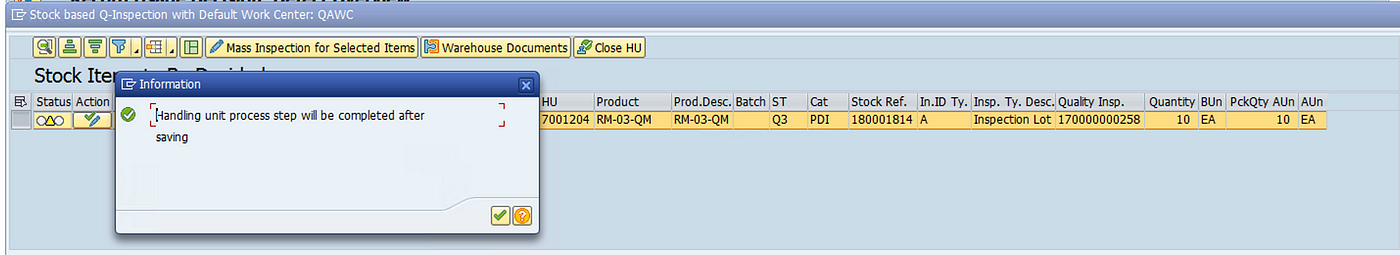

Below message will pop up.

Once that is done, click on Okay and press the save button

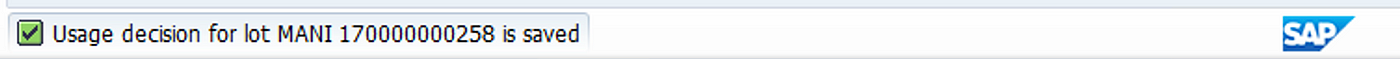

Below message will appear in the bottom of the screen.

Here, all the Quality inspection steps are completed and inspection lot is completely processed.

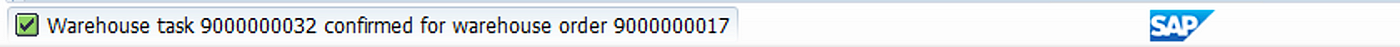

Now we need to putaway the stock from quality work center to the physical storage bin.

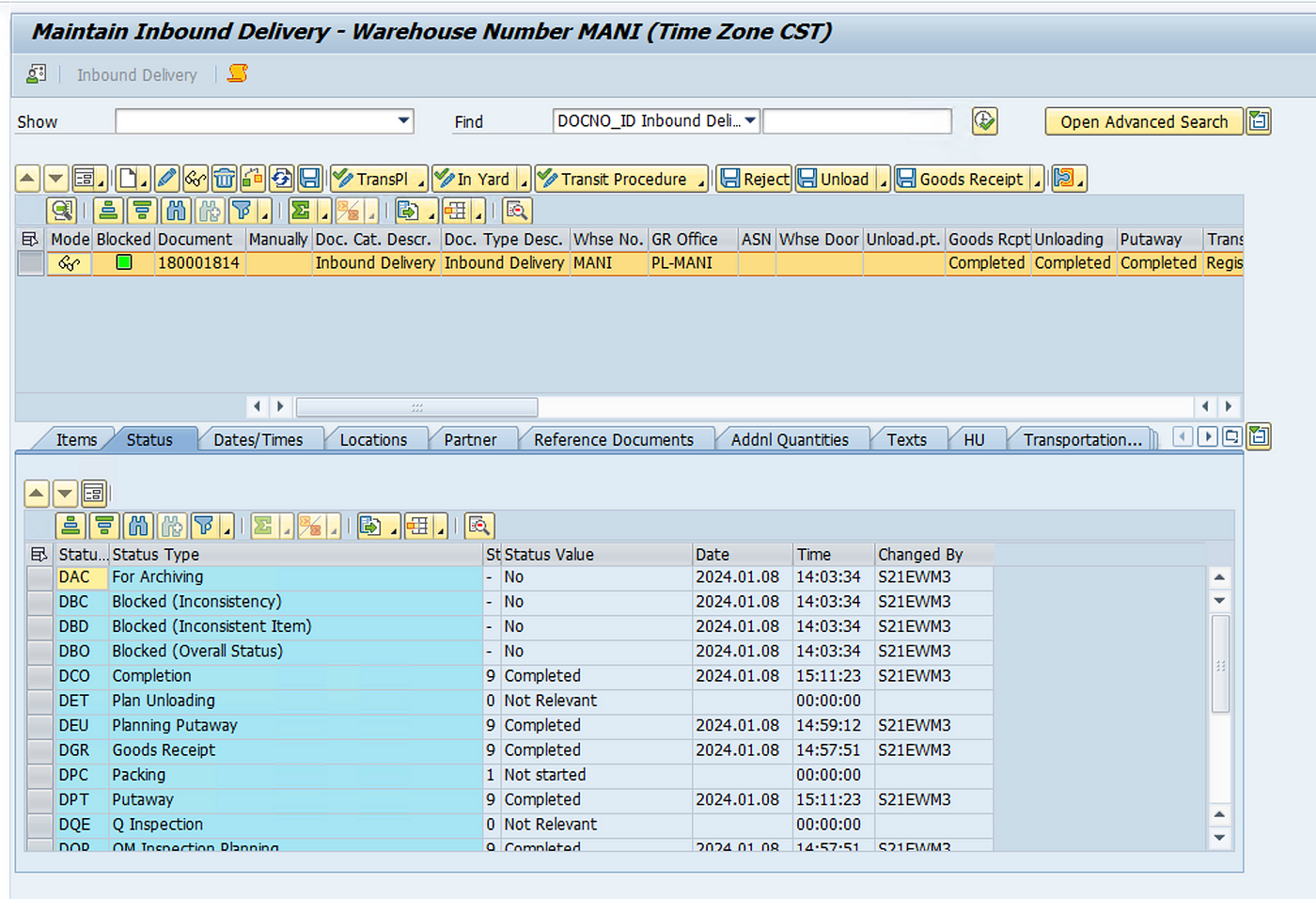

We can see in the below screenshot that all the warehouse operations are complete and stock has moved to storage type 0030.

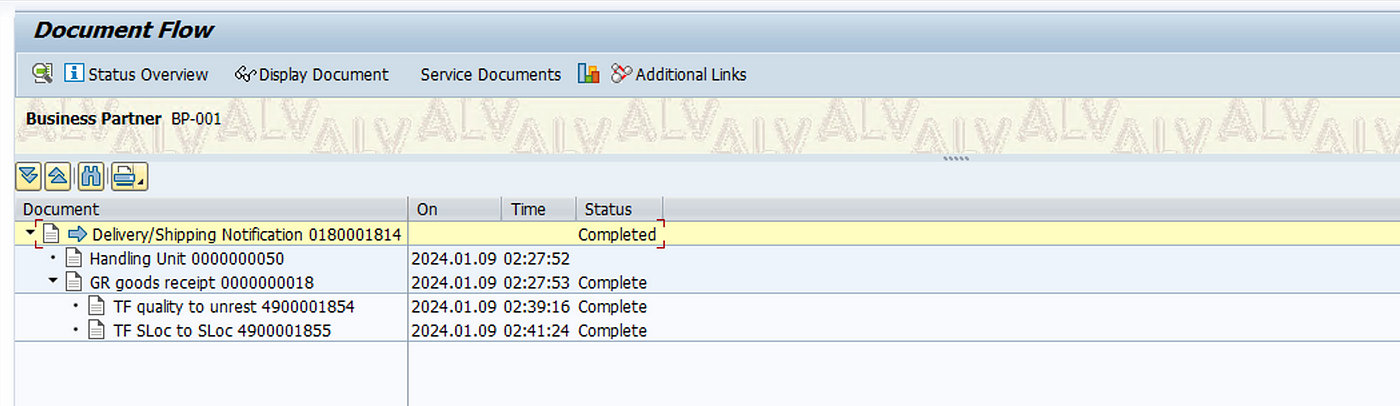

We can also check the document flow in S4 IDN.

We can also check the stock in EWM WH Monitor or MMBE in S4.