Pack Spec Configuration and Business Process

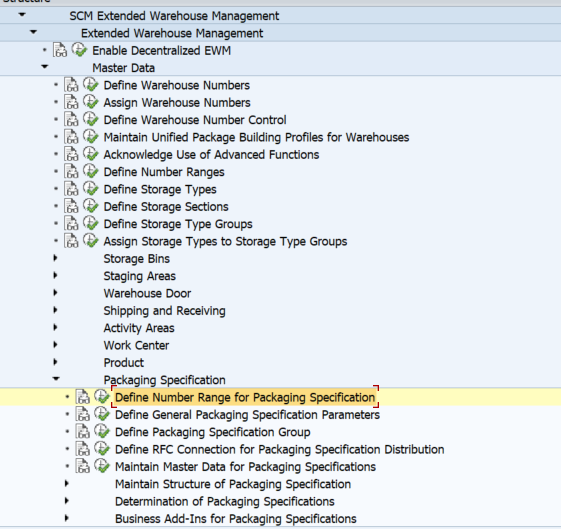

Step 1: Create a number range for PackSpec

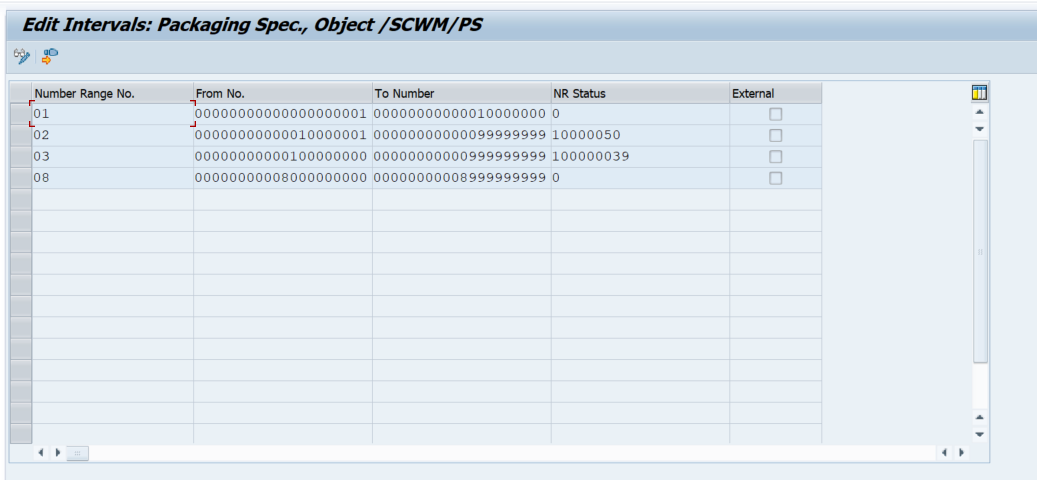

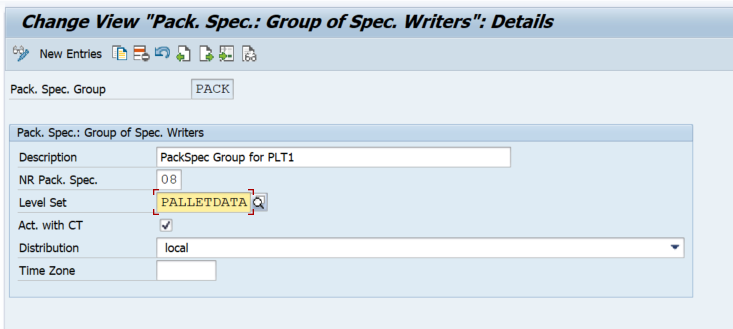

Step 2: Define PackSpec Group

In this IMG activity, you create groups for packaging specifications.

A group consists of a description, the assignment of a number range interval, and a level set and is used in the authorization object for packaging specifications.

Furthermore, you specify whether packaging specifications of this group are to be distributed to other SCM systems.

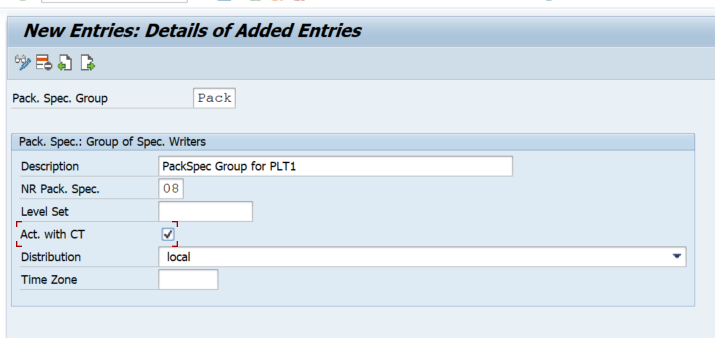

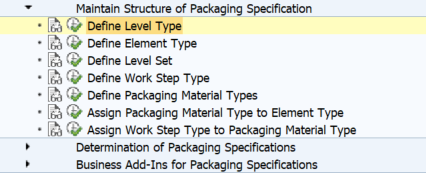

Step 3: Maintain PackSpec Structure

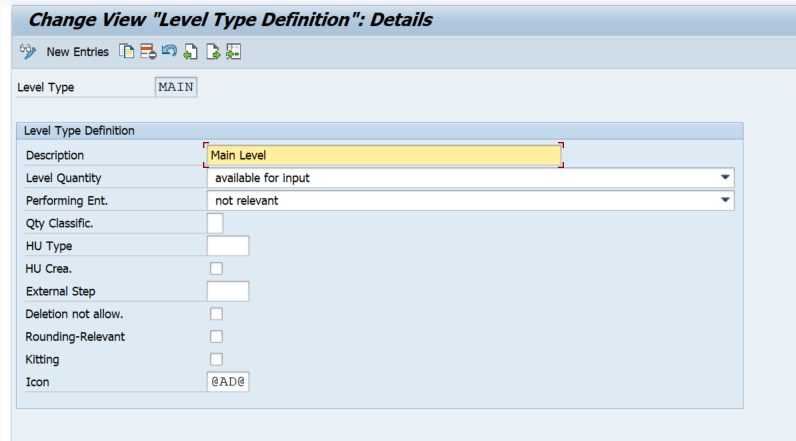

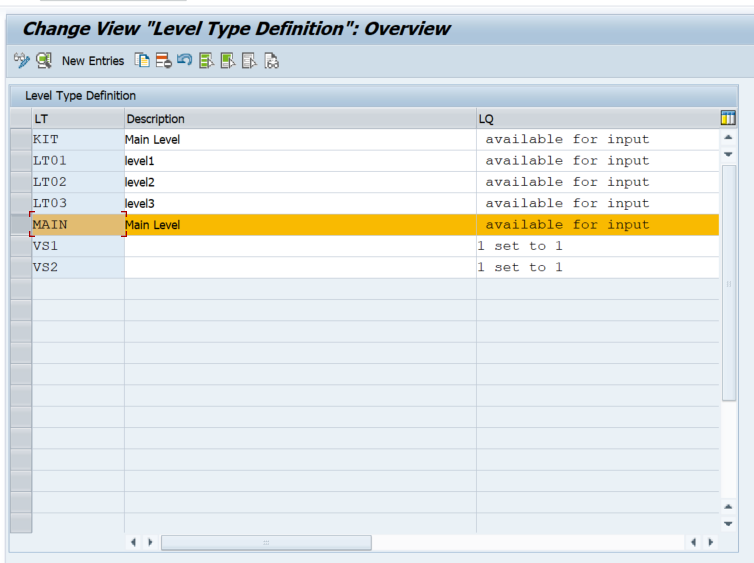

Define Level Type

In this IMG activity, you create level types. A level type consists of a description and various default values. A level type is a prerequisite for a level set.

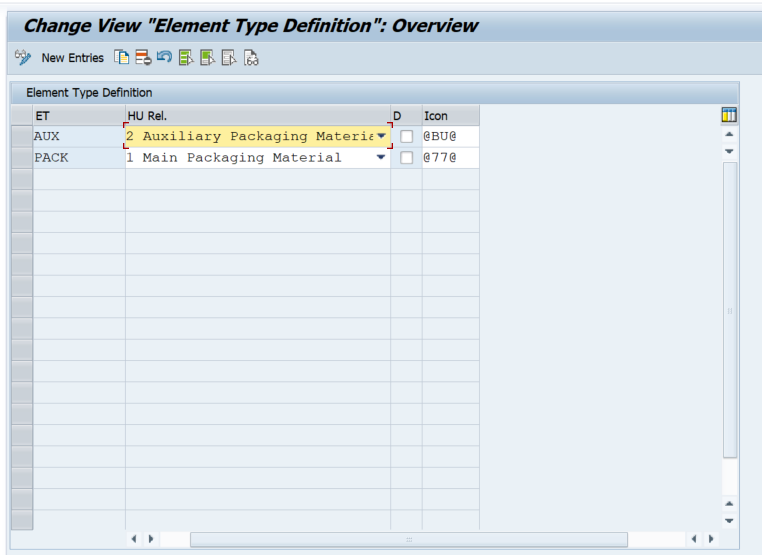

Define Element Type

In this IMG activity, you create element types. An element type consists of a description and various default values. An element type is a prerequisite for a level set.

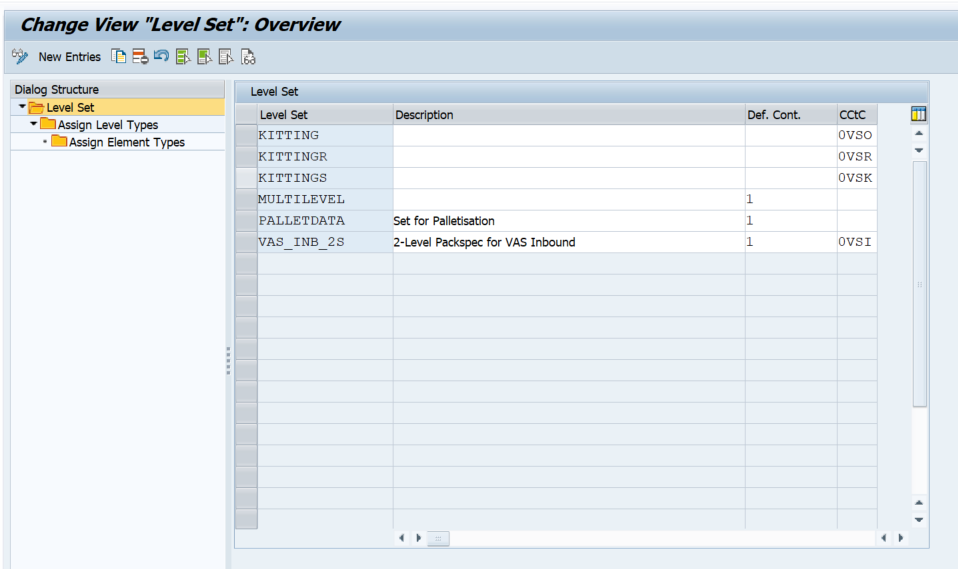

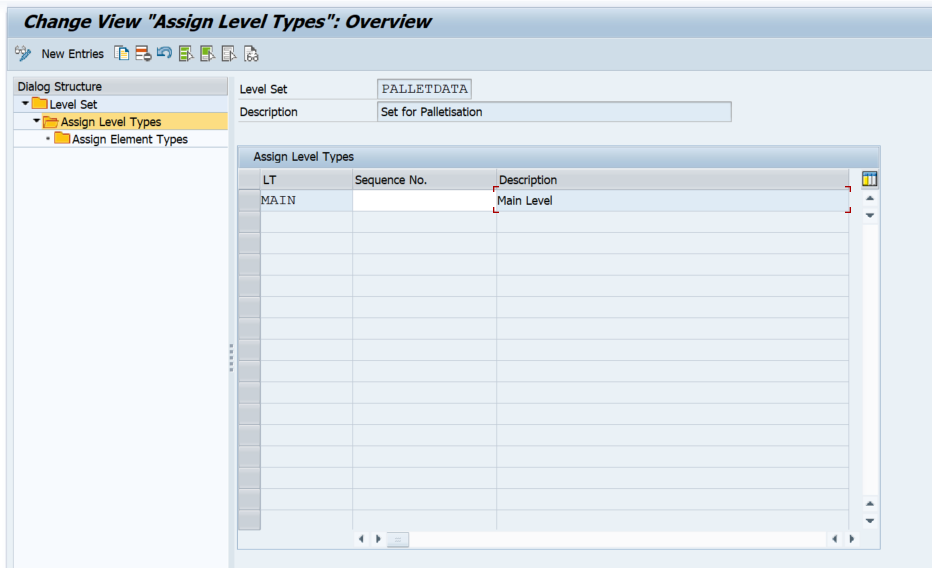

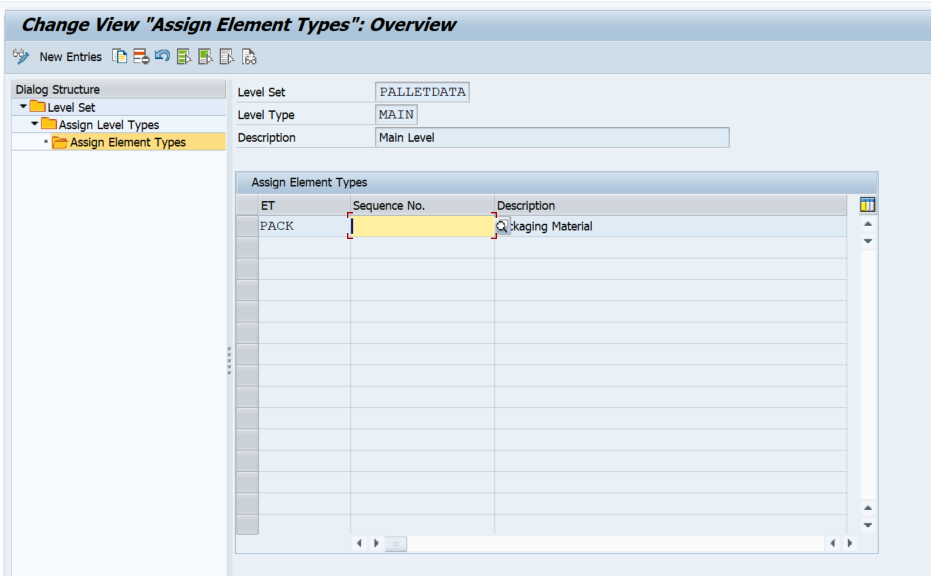

Define Level Set

In this IMG activity, you define level sets. A level set defines the structure of a packaging specification. It consists of level types and element types.

It enables you to predefine a uniform structure for packaging specifications in your system.

If a user creates a packaging specification with reference to this level set, the system adopts all the default values, and the newly created packaging specification already contains empty levels and elements.

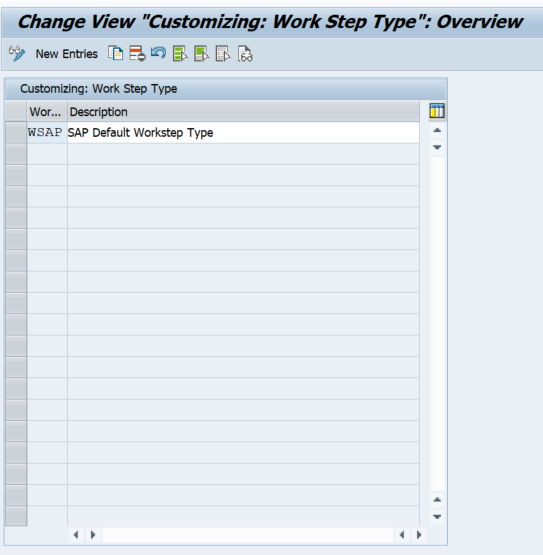

Define Work Step Type

In this IMG activity, you define packaging work step types. The work step types ensure a logical grouping of work steps.

You can assign a work step to one work step type. You can use the work step type to restrict permissions of work steps for packaging material. These permissions are ensured by assigning work steps to packaging material types.

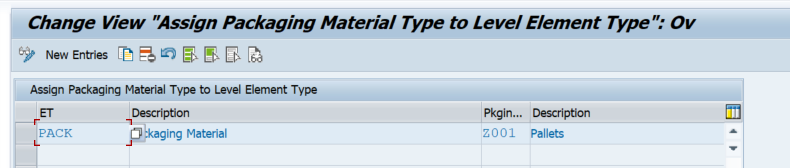

Assign Packaging Material Type to Element Type

In this IMG activity, you can assign permitted packaging material types to element types. You can assign more than one packaging material type to an element type.

If packaging material types are assigned to an element type, then only packaging materials that belong to these packaging material types are valid for this level element in a packing instruction.

If no packaging material types are assigned to an element type, then all packaging materials are valid in the level element.

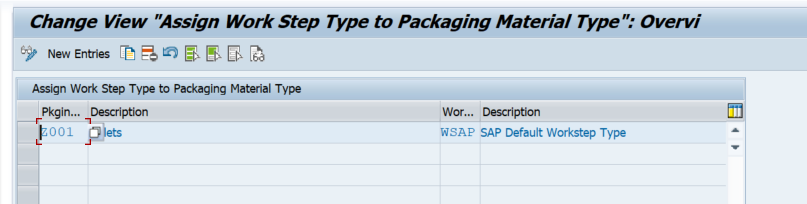

Assign Work Step Type to Packaging Material Type

In this IMG activity, you can assign permitted work step types to a packaging material type. The system takes this assignment into account during the maintenance of packing instructions.

You can assign several work step types to a packaging material type.

If no work steps are assigned to a packaging material type, then all work step types are permitted during maintenance of a level element in a packing instruction, if you are using a packaging material from the given packaging material type.

Assign or maintain the level set in the packaging specification group

Step 4: Maintain the determination rule for PackSpec

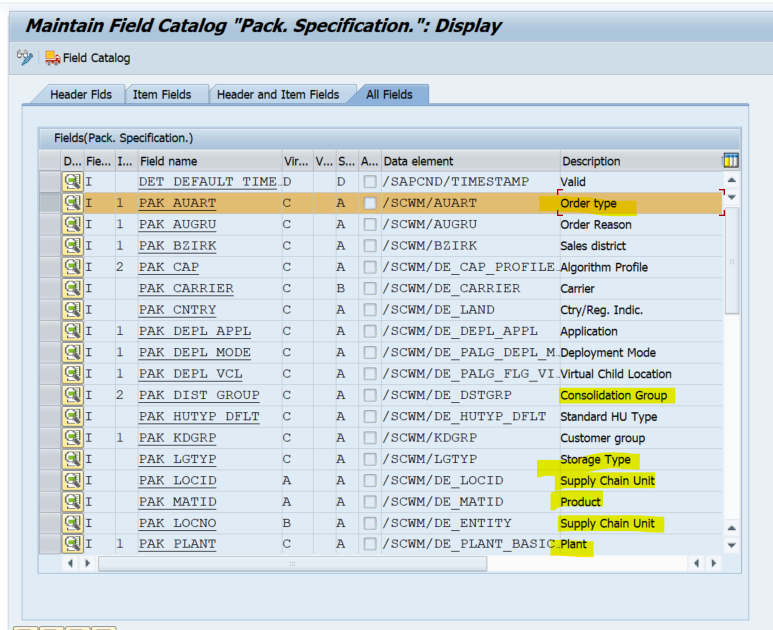

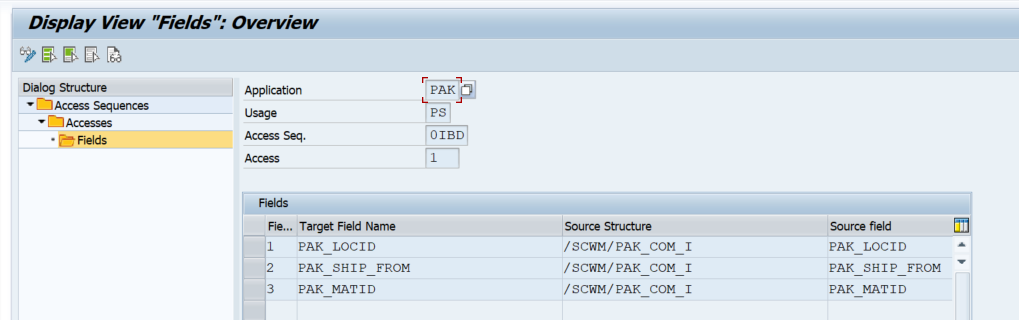

- Create Field Catalog: you can maintain the field catalog for packaging specifications. The field catalog contains the fields you are allowed to use for defining condition tables. Field catalog maintenance is divided into three screen areas:

- Field catalog area

- Detail area for field and data element (can be displayed/hidden)

- Detail area for the log (can be displayed/hidden)

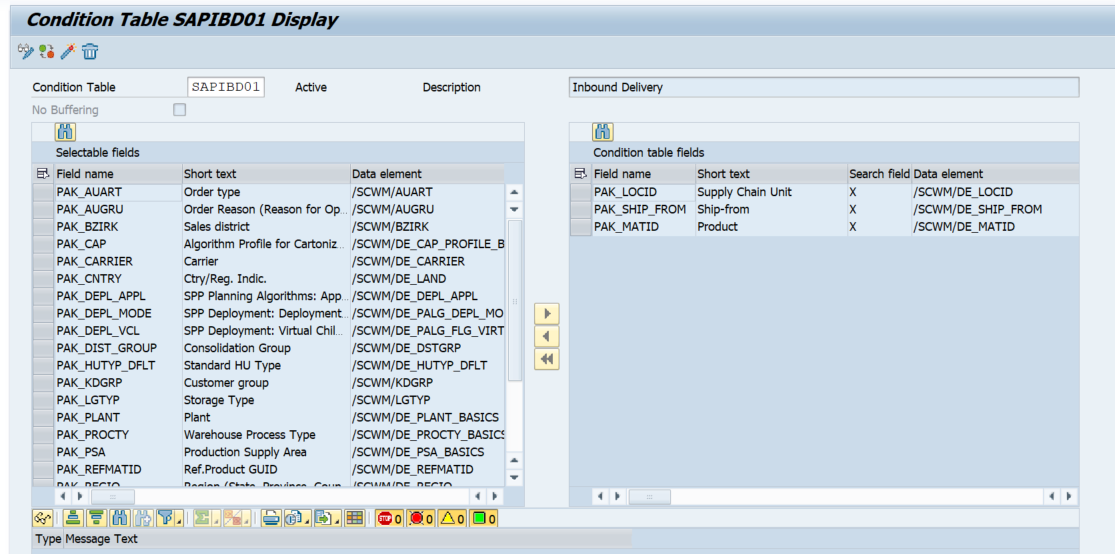

2. Define Condition Tables

In this IMG activity, you define packaging specification dependencies. For example, you can make packaging specifications dependent on the material to be packed and the recipient of the goods. In this case, the system finds a particular packaging specification according to the product and goods recipient specified.

You define these dependencies using the condition tables. You define the combination of fields in a condition table (for example, product and goods recipient) on which you want to make the packaging specification determination dependent. Later on, you fill this condition table with content, that is, with concrete information, using the condition records.

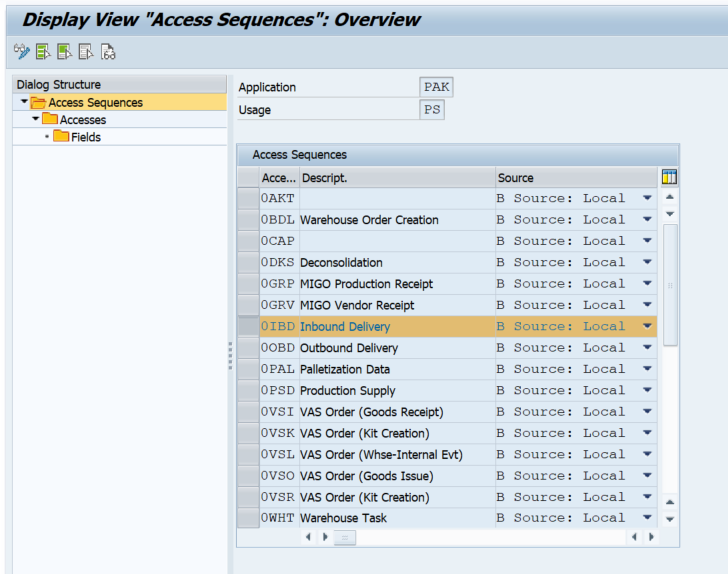

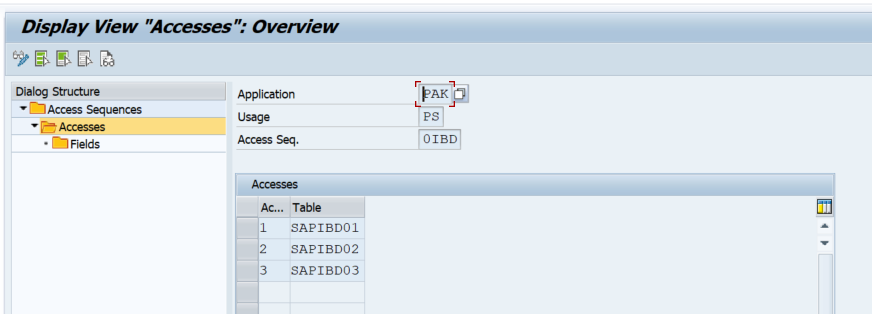

3. Define Access Sequences

The access sequence is a search strategy that the SAP system uses to search for valid determination records for a packing instruction condition type.

Each condition table contains a particular combination of fields that the system is to search for in the condition records. The search sequence should go from special to general condition records:

For example, you can define in packaging specification determination that the SAP system first searches for a packing instruction only using the combination of product and goods recipient (you define this combination using the condition tables) and then only using the goods recipient.

You use the exclusive indicator to define that the system finishes searching in additional condition types from the access sequence once it has found a valid condition record. All valid condition records of this condition type are returned. The logical conditions are evaluated once the actual determination has taken place. This means that in some processes it could be that no condition record is found.

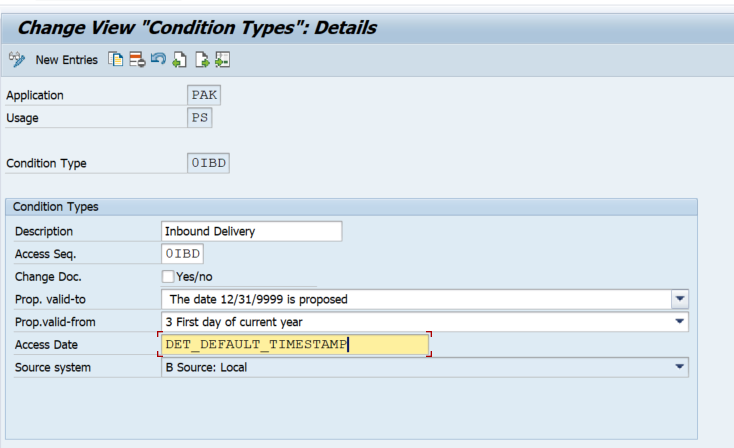

4. Define Condition Types

For example, you can define the condition type Pack in Shipping and assign packaging specifications to this condition type. In this way, the condition types are used to group the packaging specifications permitted for a certain area. In each condition type you specify an access sequence that you use to define the fields that the SAP system searches for a valid determination record (condition record).

You always define determination records for a condition type.

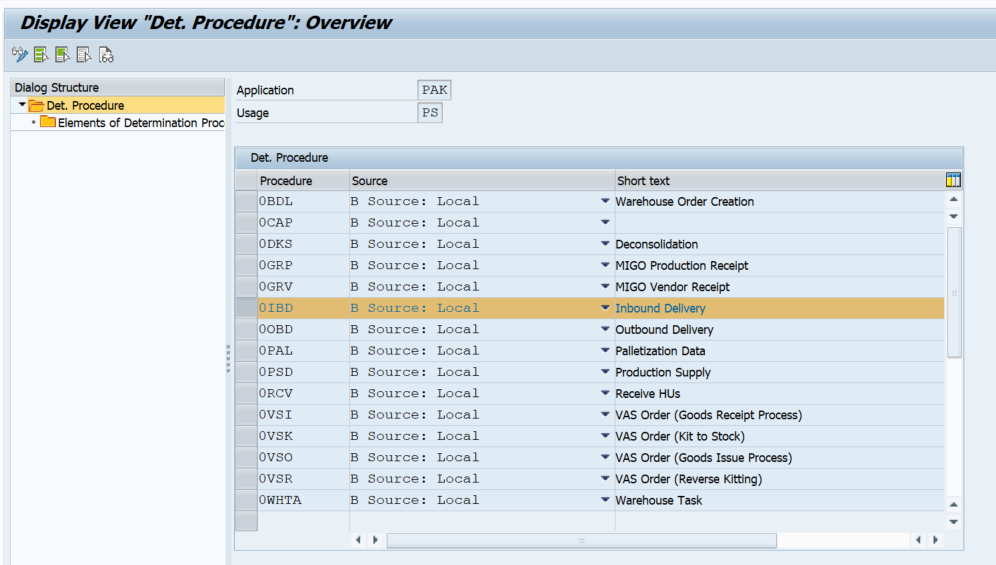

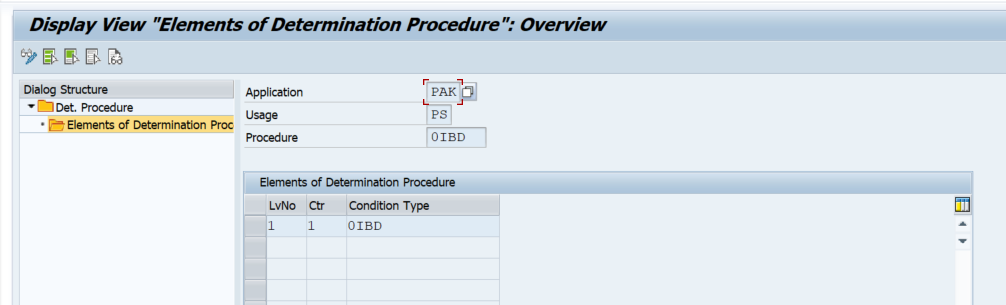

5. Define Determination Procedure

In a packaging specification procedure, you define which condition types are taken into account and in which order. When determining the packaging specification, the system automatically determines which procedure is valid for a business transaction and takes into account the determination types contained within, one after the other.

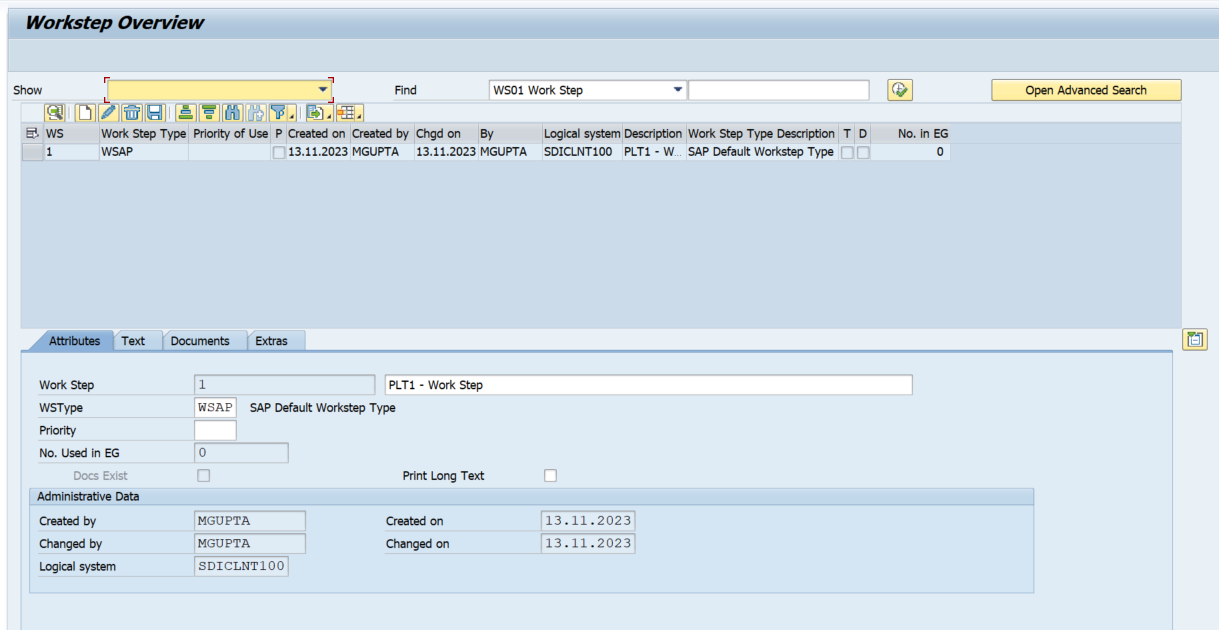

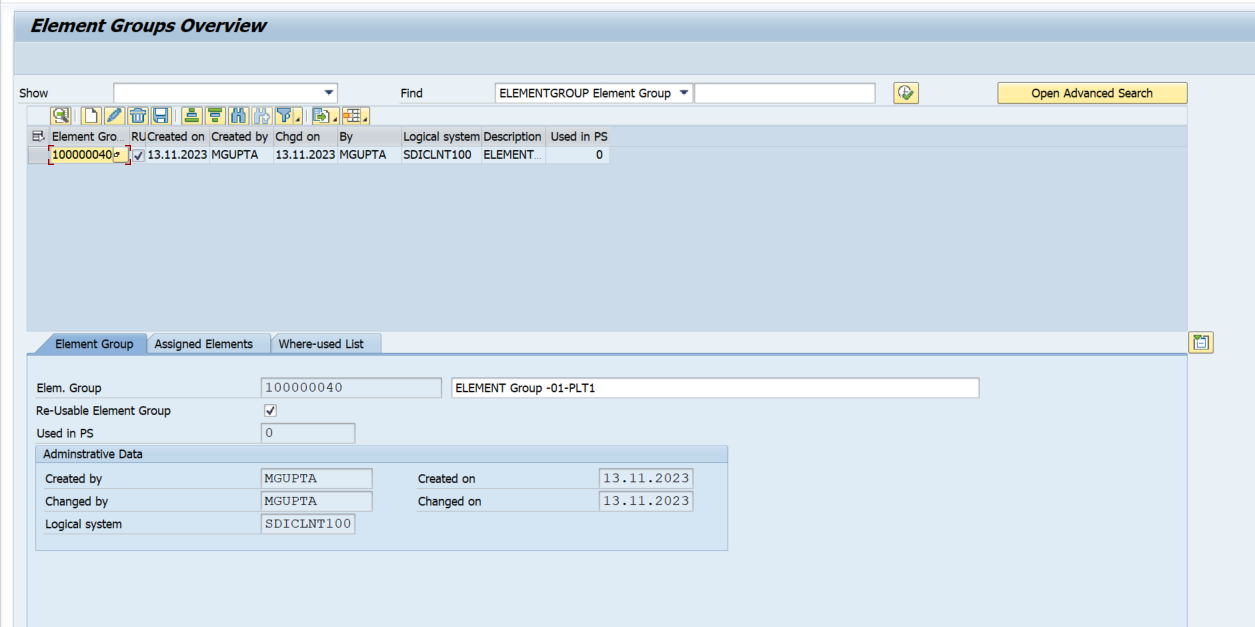

Step 5: In SAP easy access maintain one packaging work step and one level element group

Maintain packaging work step (T.Code : /N/SCWM/PSWORKSTEP)

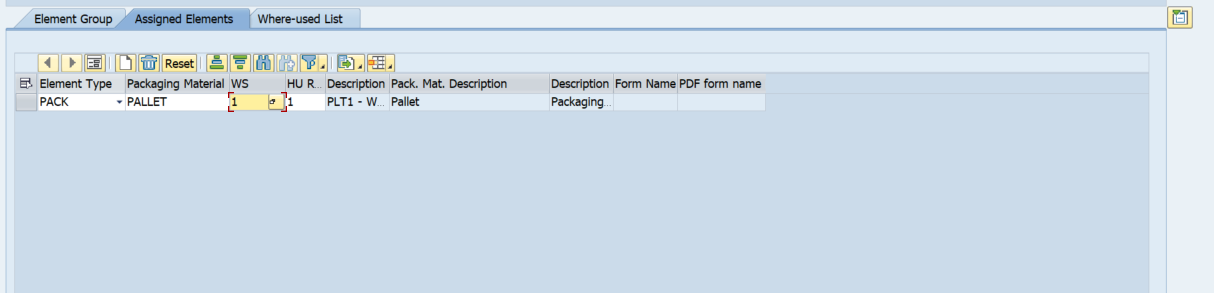

Maintain level element group (T.Code : /N/SCWM/PSEG)

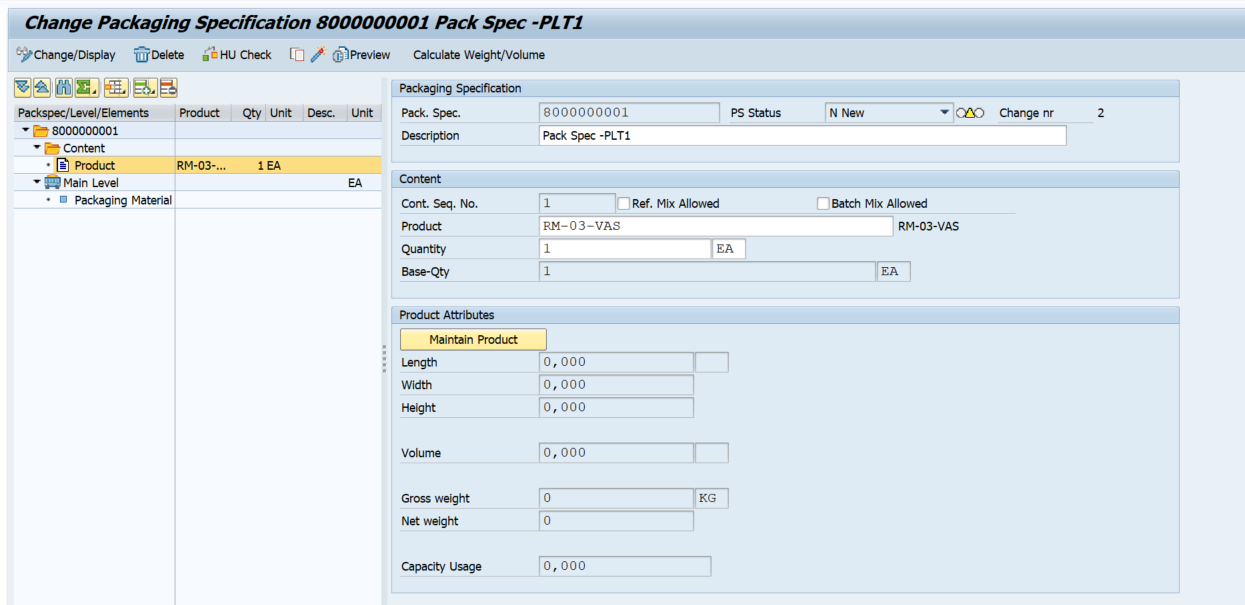

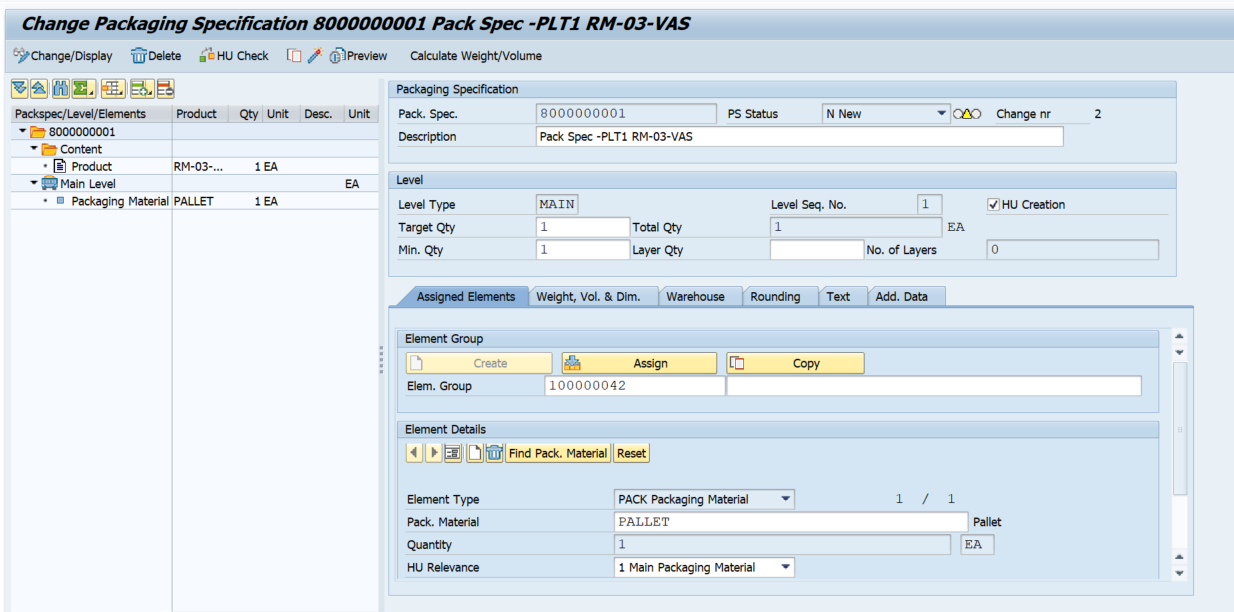

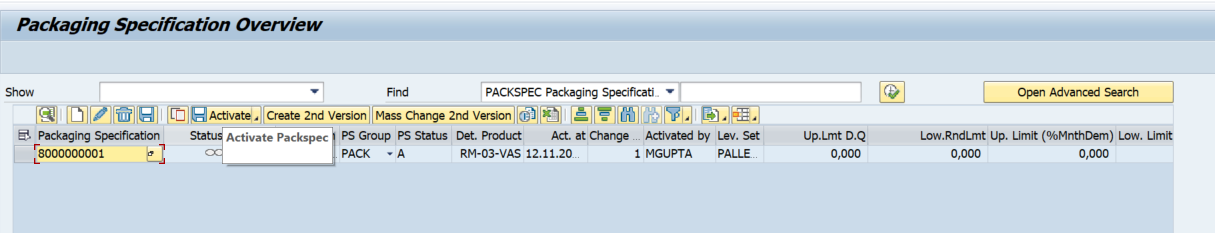

Create or maintain packaging specification ( T.Code : /SCWM/PACKSPEC)

Activate the packSpec

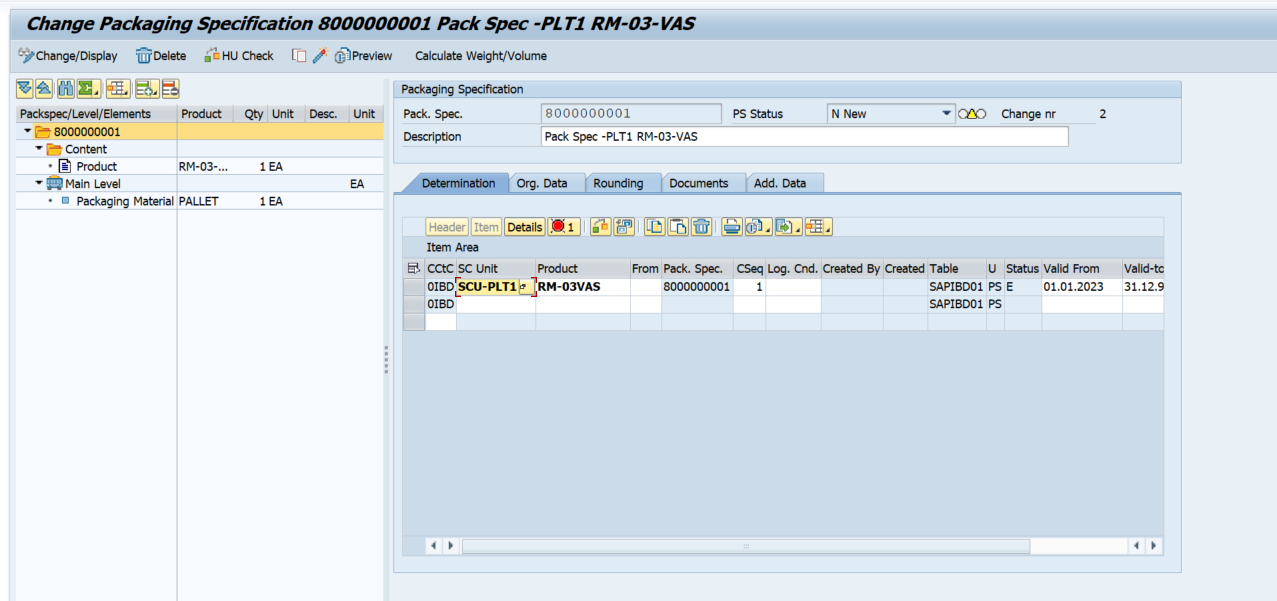

We will now test How PackSpec works in the EWM system

Step1: Create an IBD in S4

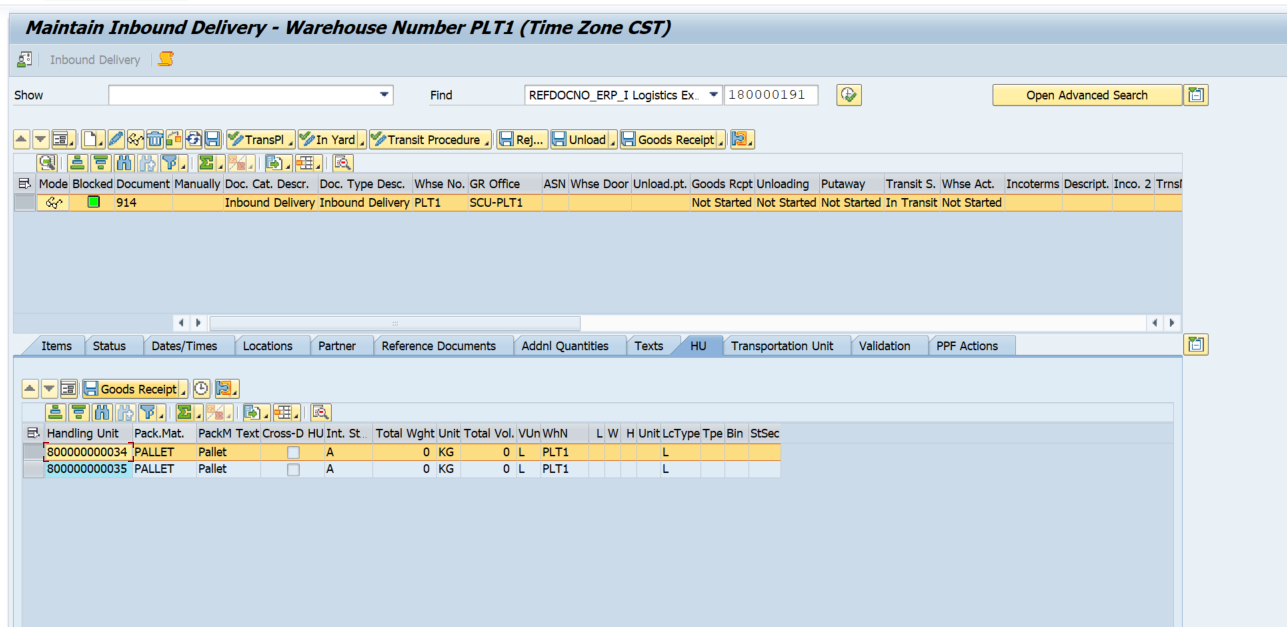

Step2: Check the delivery in EWM /SCWM/PRDI

in the Inbound Delivery, we can see that 2 HU’s were created.