SAP EWM CF132: Physical Inventory Process Configuration and Business Process | SAP EWM Configuration

We will go through the EWM PI configuration and Business Process.

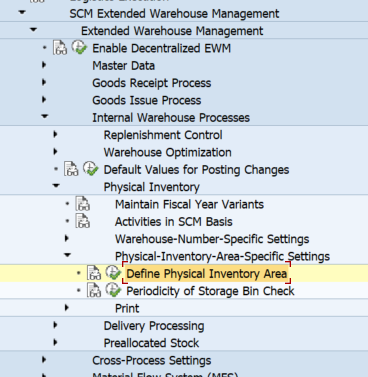

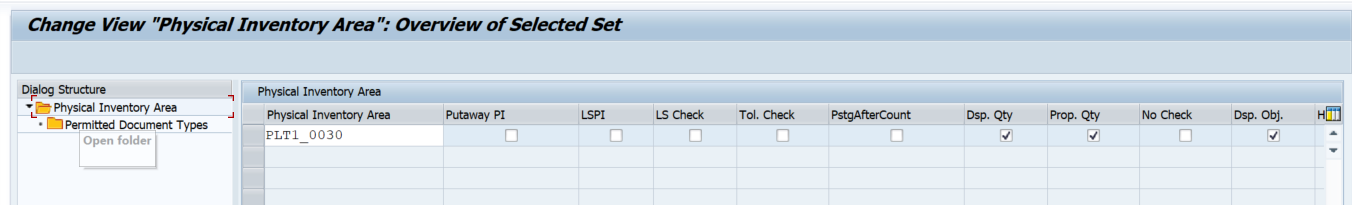

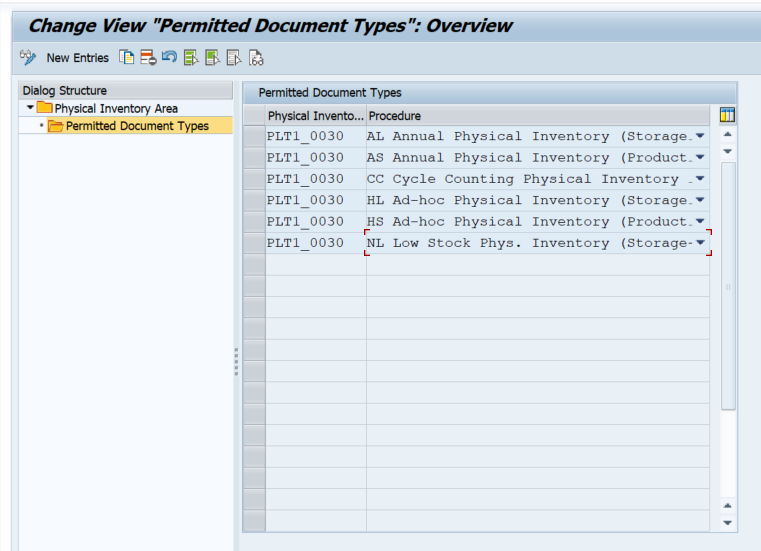

Step 1: first we need to define the PI area

You specify the following per physical inventory area:

- Whether a putaway physical inventory is allowed (once per PI period)

- Whether a low-stock/zero-stock physical inventory is allowed (once per PI period)

- Whether a low-stock/zero-stock check is to be carried out when the warehouse task is confirmed

- Whether the document is to be posted automatically after the count (this depends on the user’s allowed tolerance values)

- Whether the book inventory is to be proposed at the time of the count and at the time of printout (does not apply to radio frequency environments)

- Whether the inventory quantity is to be proposed at the time of the count but not at the time of printout (does not apply to radio frequency environments)

- Whether the product data is proposed in the case of the storage-bin- specific physical inventory

- Whether it is allowed to count a handling unit as complete

- Whether you want to count collectively the number of handling units or the number of items inside a handling unit. (The prerequisite of activating handling unit collective counting is to select both HU Complete checkbox and Display Item Objects at Time of Count Entry checkbox)

- Whether the product data is included in printouts

- The threshold value for the low-stock physical inventory or check (in the case of the zero-stock physical inventory or check, leave the field initial or zero)

- Whether to ignore the setting of the default stock type that is set on the warehouse level for a physical inventory area.

- Whether to enable a tolerance check for low-stock check at stock removal before the system posting an inventory difference to difference analyzer. (If an inventory difference doesn’t pass a tolerance check, the system cancels the low-stock check.)

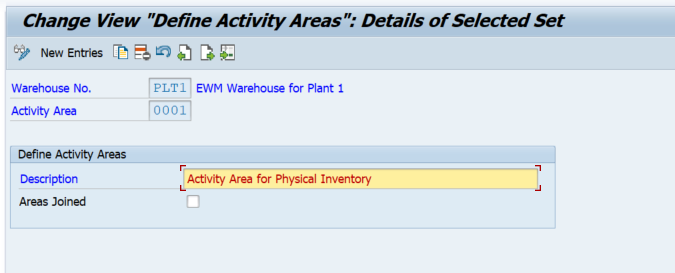

Step 2: We need to define Activity Area for PI

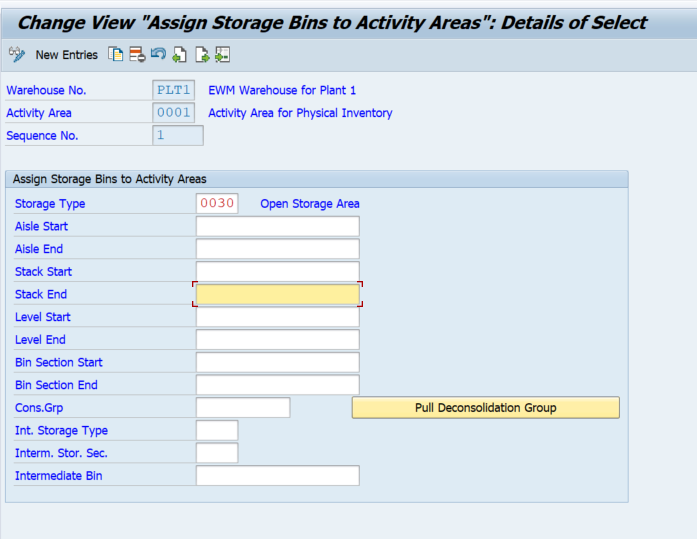

Assign bins to the PI Activity Area

Execute /o/scwm/sbst and assign the act area to the bin

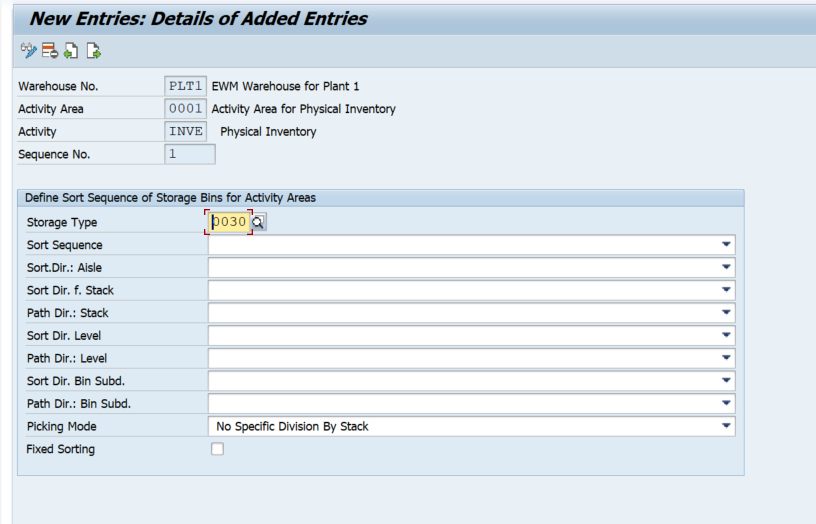

Assign Activity PI to AA 0001

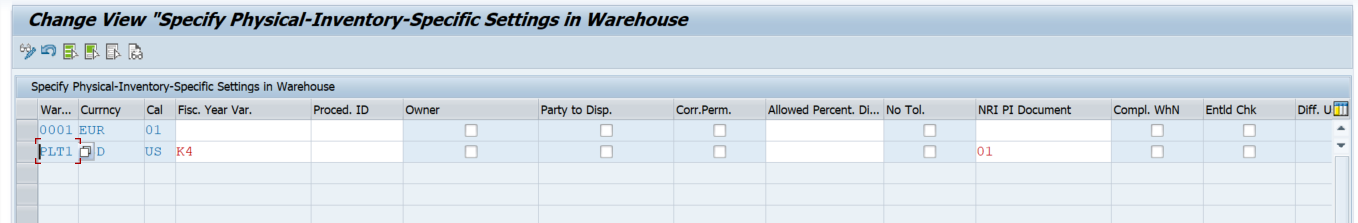

Step 3: WH Specific settings

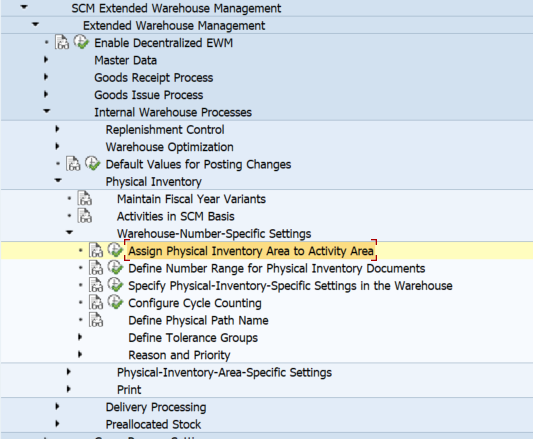

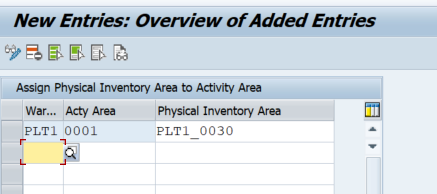

Assign PI area to Activity Area

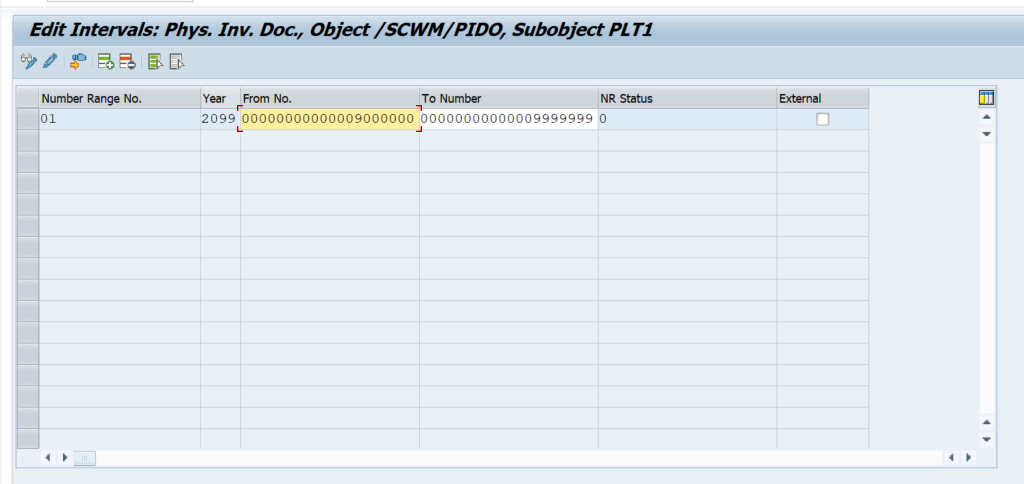

Assign number range

you can make the following physical-inventory-specific settings for each warehouse:

- Currency unit

- Factory calendar

- Period (fiscal year)

- Determination procedure for printing physical inventory (PI) documents to use

- Month and day of (yearly) PI period, if different to fiscal year

- Whether the owner is proposed in the physical inventory count

- Whether the person authorized to draw is proposed in the physical inventory count

- Whether adjustment postings are allowed in the Difference Analyzer

- Permitted percentage deviation when inputting a quantity for the physical inventory count

- Whether the percentage deviation for the physical inventory count is to be checked

The percentage tolerance check is only used when inputting information on the user interface, it is not used when saving or posting. Separate tolerance checks are available for saving and posting.

- Assignment of a number range interval to physical inventory documents

- Whether physical inventory completeness should always be determined at the warehouse level only

- Whether the system checks if the counter entered a valid party entitled to dispose for a product when posting the results of a PI count in SAP Extended Warehouse Management (SAP EWM)

- Whether the system checks that the counter who recounts the PI documents is different from the original counter

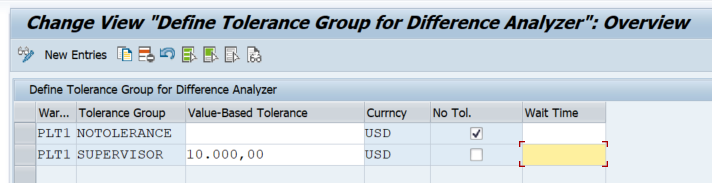

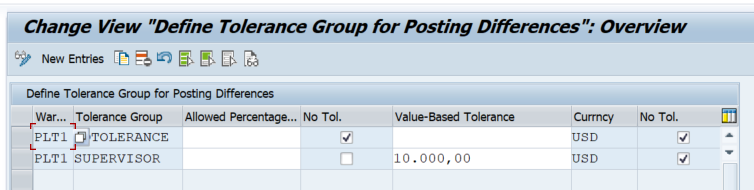

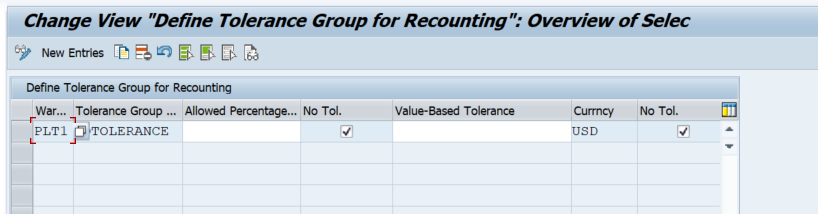

Define Tolerance Groups

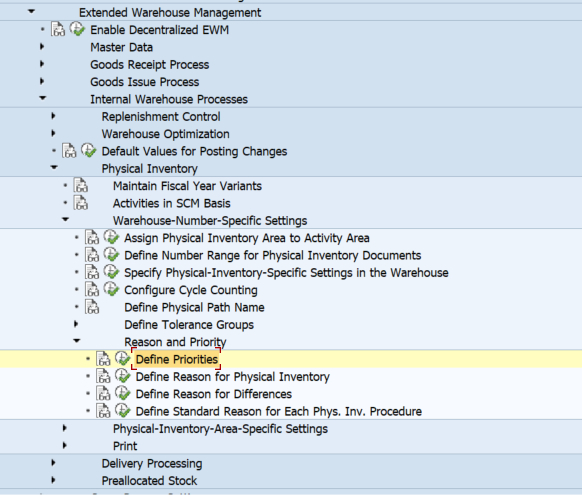

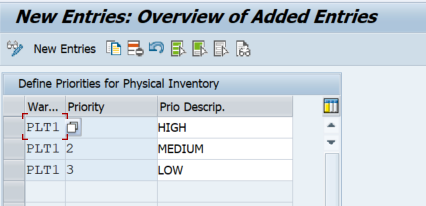

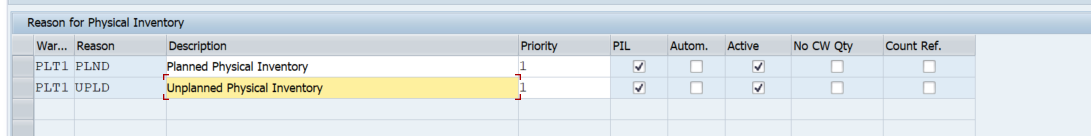

Define Reason and Priority

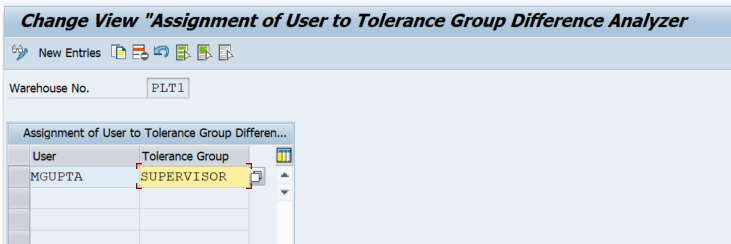

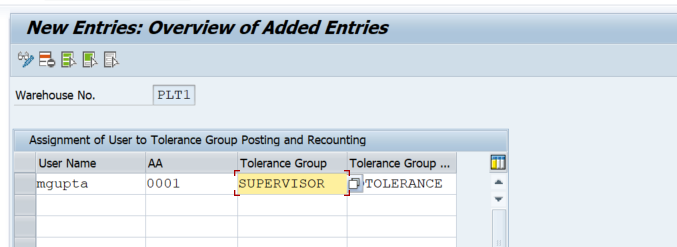

Assign a Tolerance group to Users

Steps to carry out PI at the EWM level

Annual inventory

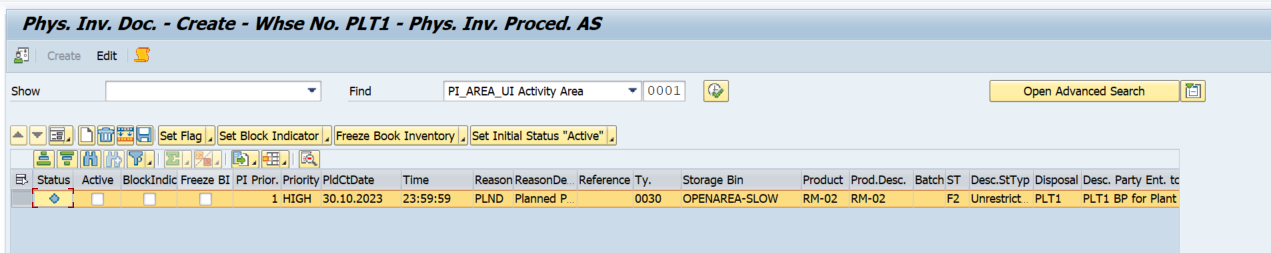

/SCWM/PI_CREATE — Create Physical Inventory Document

/SCWM/PI_COUNT — Enter Count Results

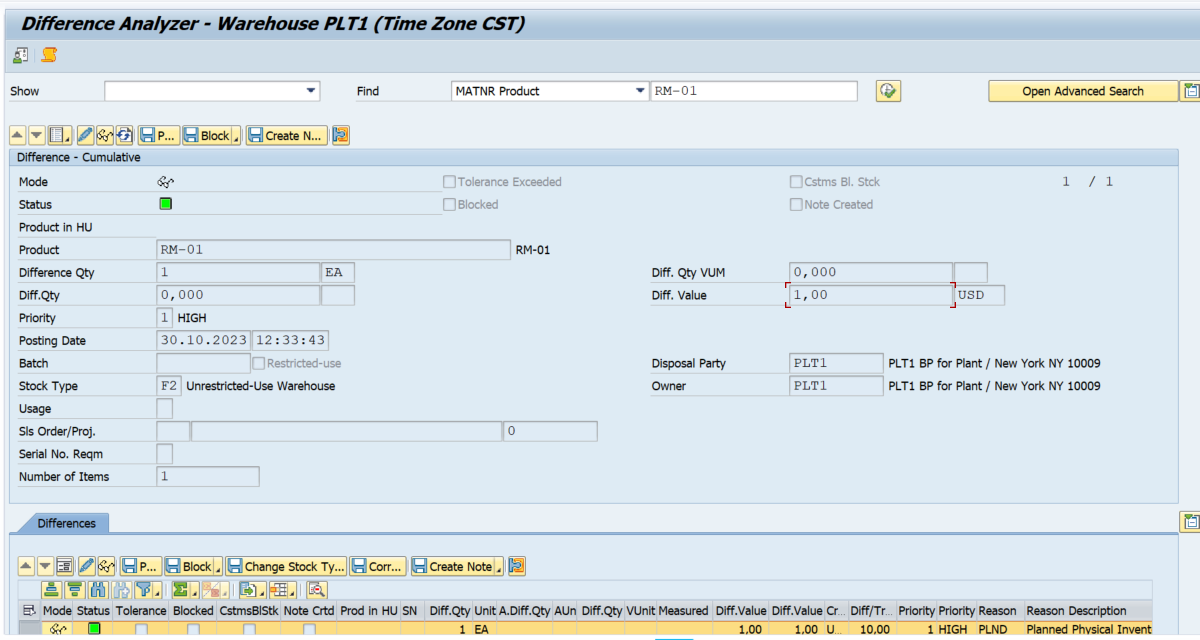

/SCWM/DIFF_ANALYZER — Difference Analyzer

/SCWM/PI_USER_DIFF — Assign User to Tolerance Group for Difference Analyzer

/SCWM/PI_USER — Assign User to Tolerance Group for Recount/Clearing

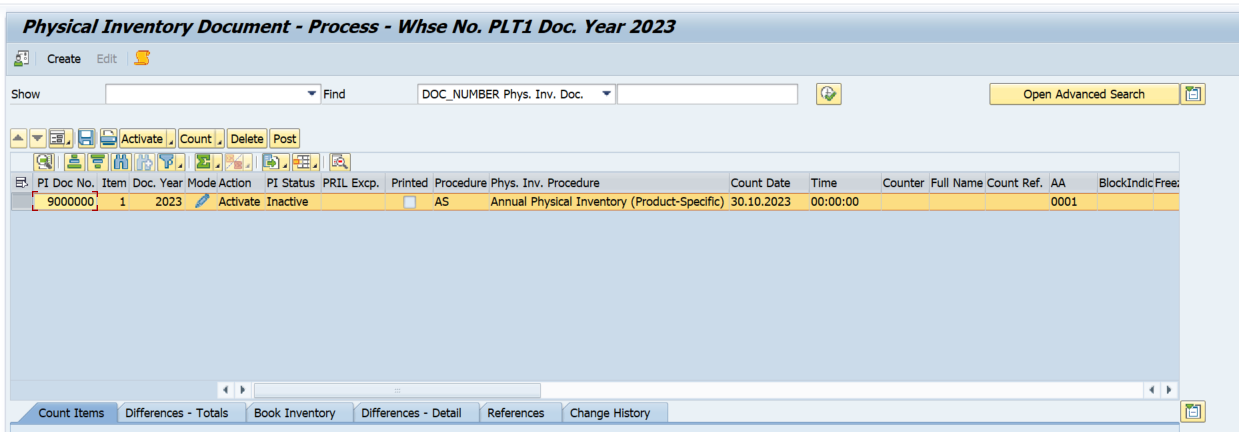

Step 1: Create PI document

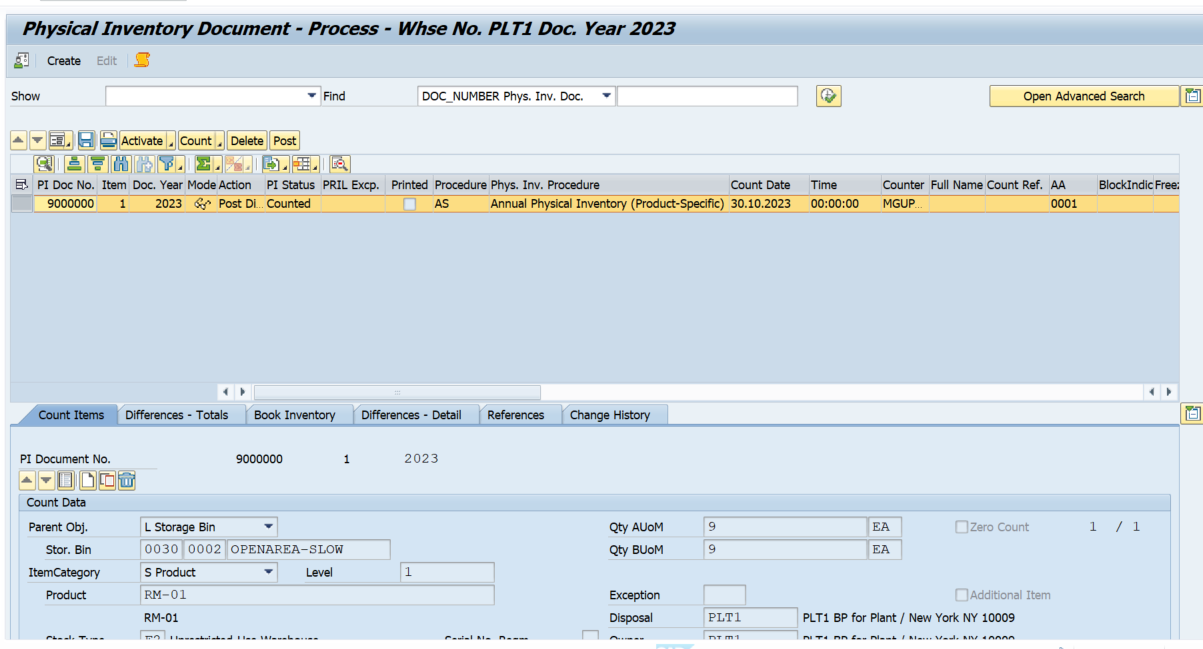

Step 2: Process PI doc and count

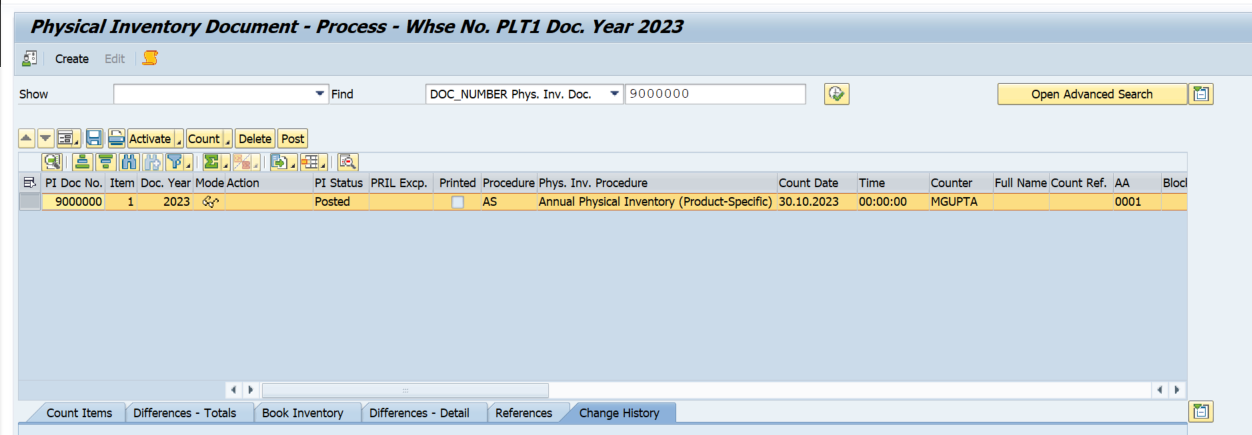

Stock is now counted- diff posting is pending, click on the post

Step 3: Analyze the Difference.

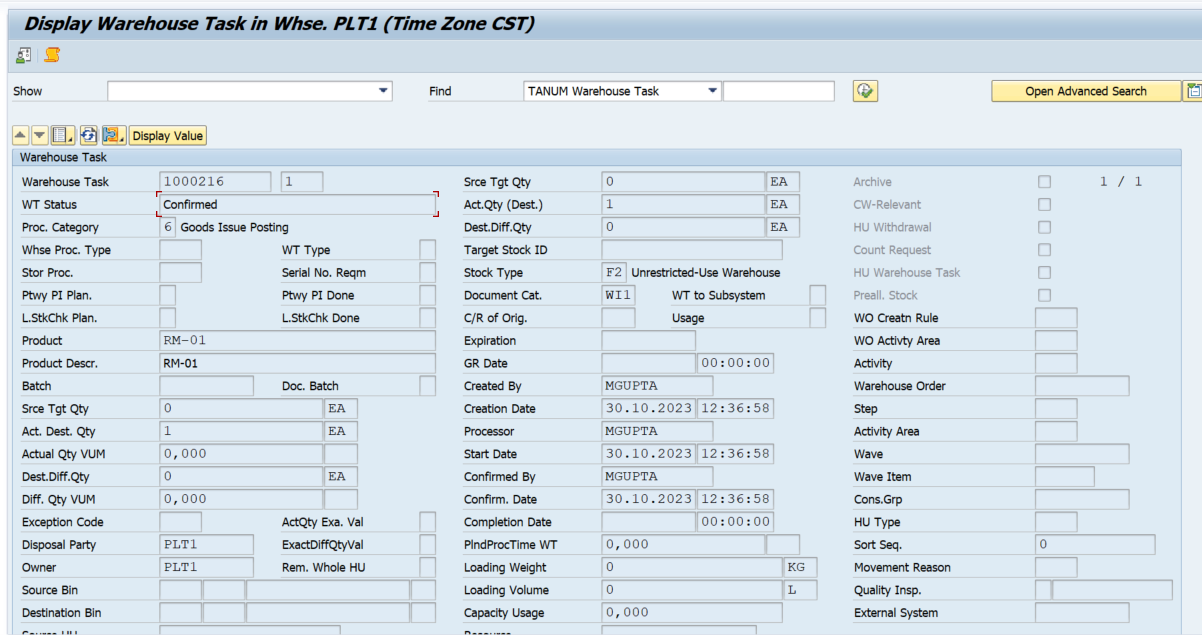

Once this WT is confirmed- The difference will be posted at EWM as well as the S4 level