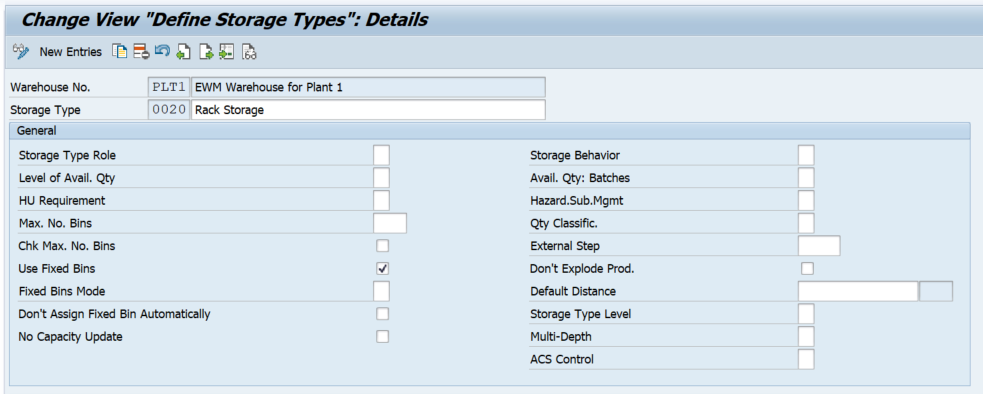

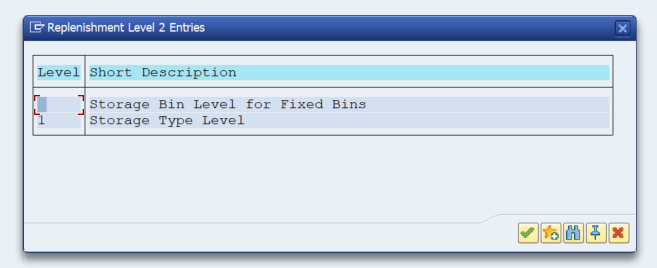

We can configure replenishment at 2 levels

- Storage Type Level — Replenishment is done for any bin within the storage type for a product based on Max-Min and Replenishment quantity provided in the Product master. If only 2 bins are allowed for a product in the storage type and replenishment quantity requires more than 2 bins to carry out, the replenishment will happen only for 2 bins.

- Storage Bin Level — Replenishment happens at the assigned Bin level based on product master data.

The strategies are available in EWM for replenishment

- Planned — This includes manually running the replenishment process, order-related replenishment which is based on open Warehouse Requests, and Crate Part replenishment which is used in Production Planning where a fixed quantity needs to be maintained for PSA.

- Unplanned — This includes Automatic replenishment which gets triggered during WT confirmation for a product and Direct Replenishment which gets triggered during the use of an exception code while doing Pick Denial.

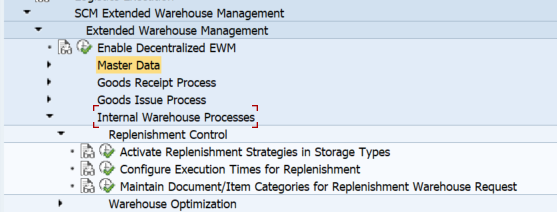

Configuration to be done for the Replenishment Process.

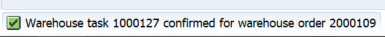

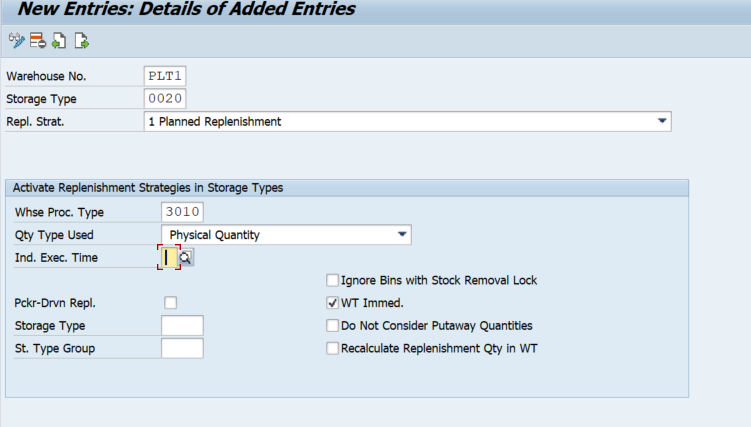

Step 1: Activate Replenishment controls at Storage Type Level

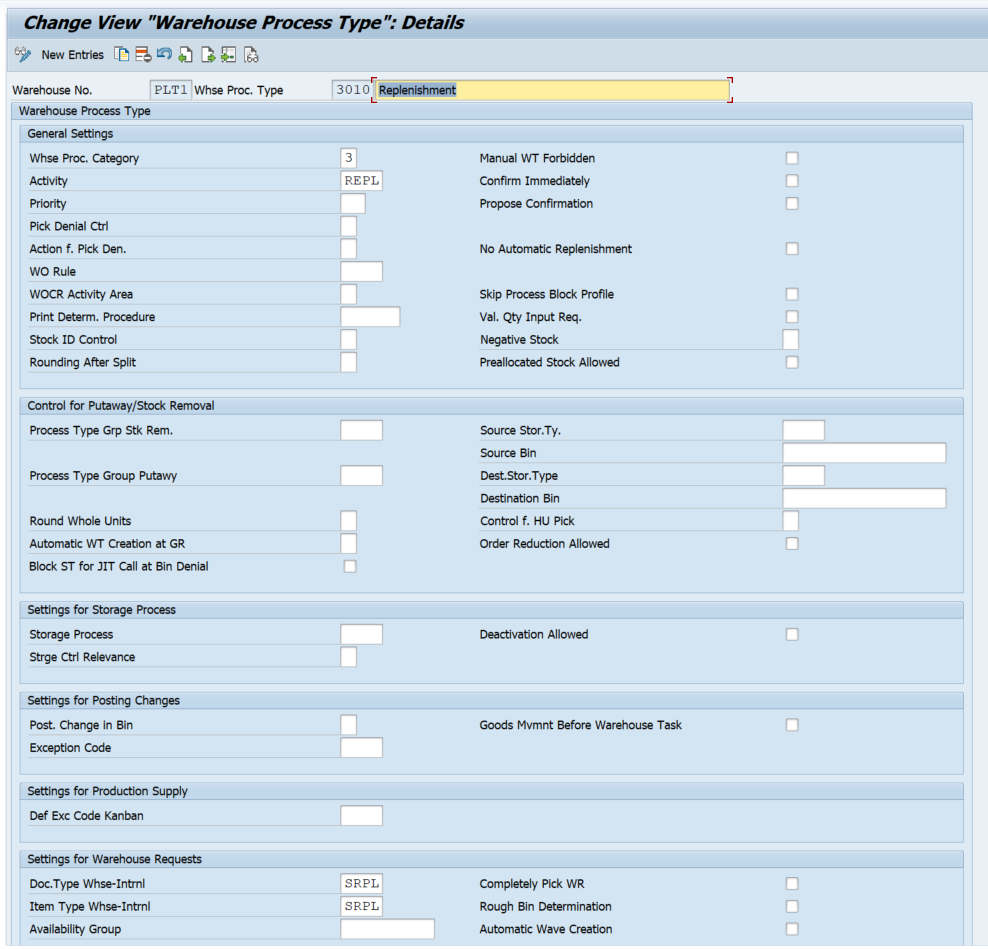

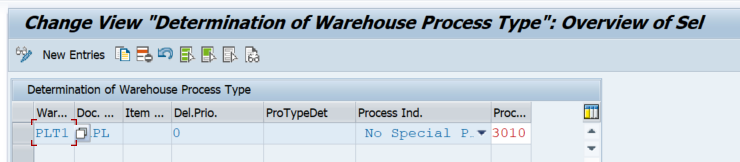

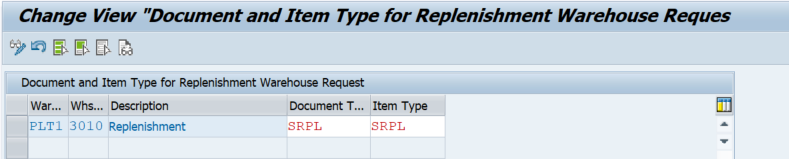

Step 2: Create WPT and Determination Rule

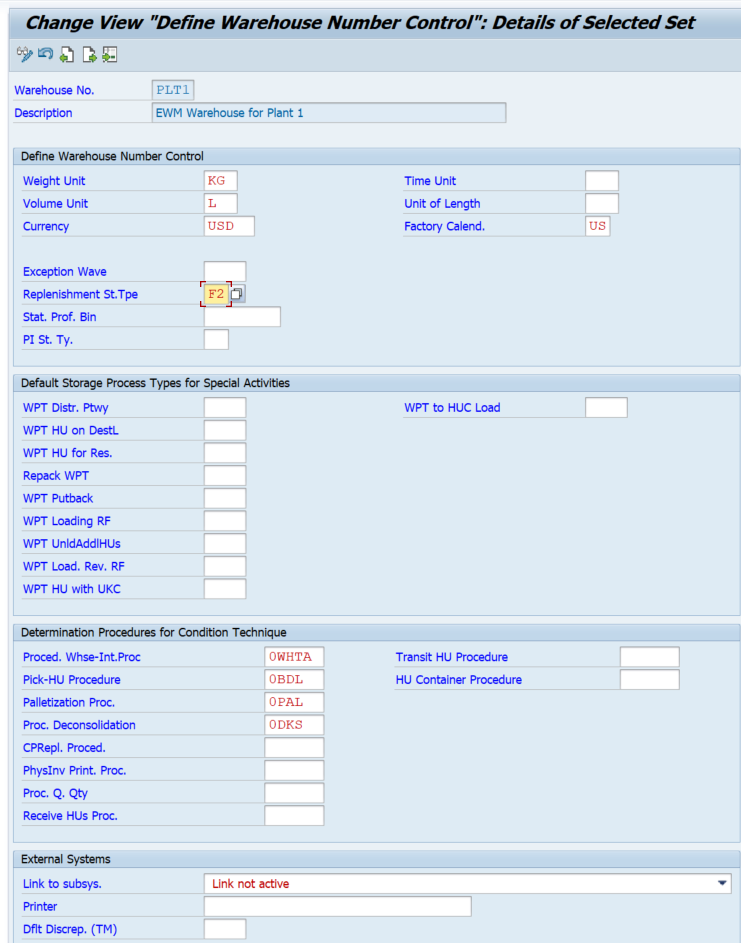

Step 3: Configure Basic Replenishment Controls

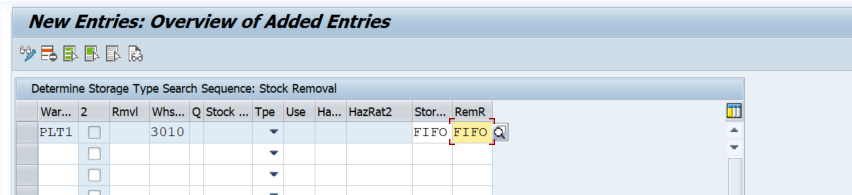

Step 4: Assign Replenishment Stock Type at WH level and Assign Picking search strategy to the WPT 3010

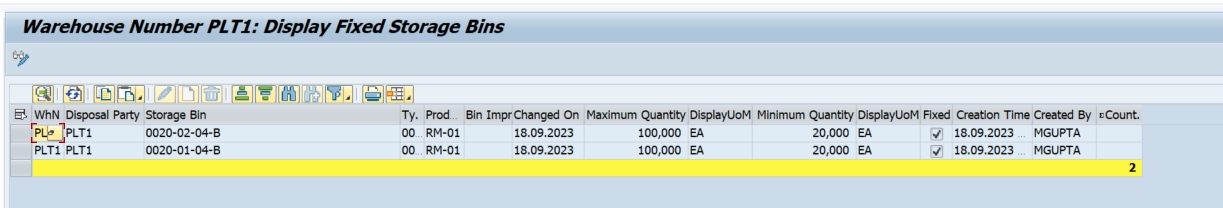

Step 5: Assign Bin from StrType 0020 to the product using T Code : /SCWM/BINMAT

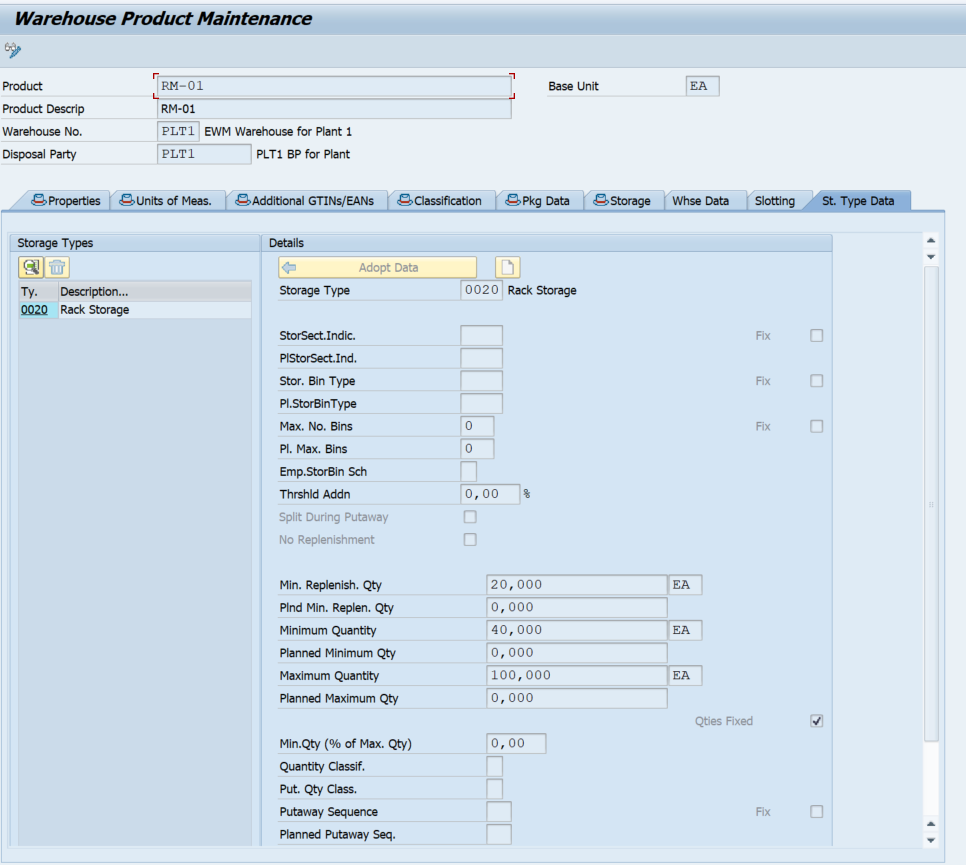

Step 6: Maintain Product master data

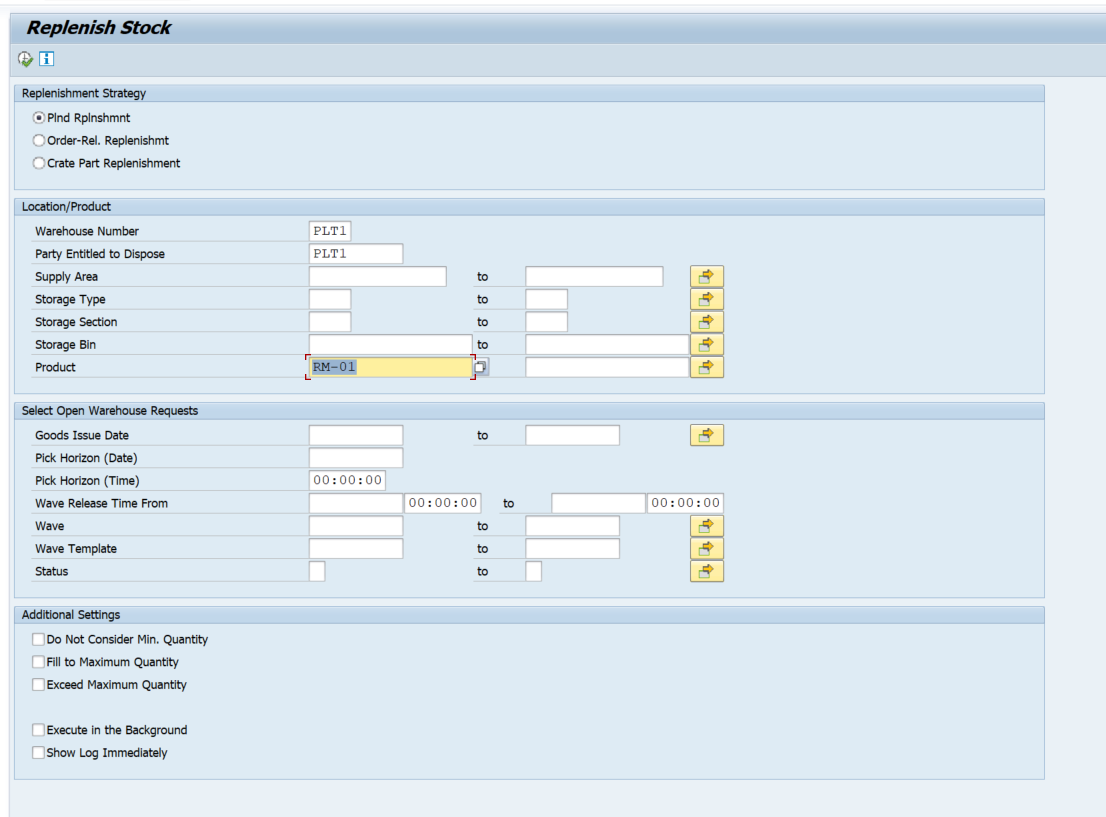

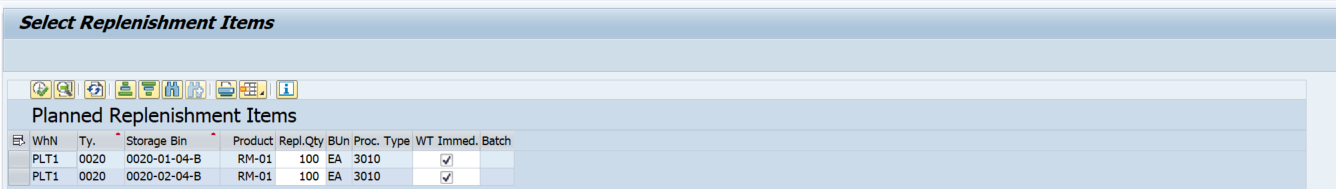

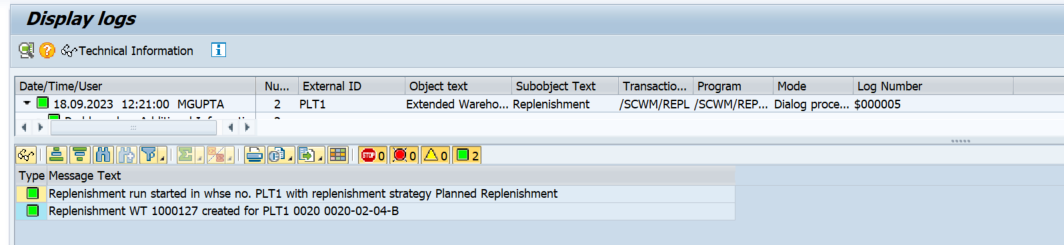

Now we will execute the planned replenishment process

Execute TCode /SCWM/REPL for replenishment

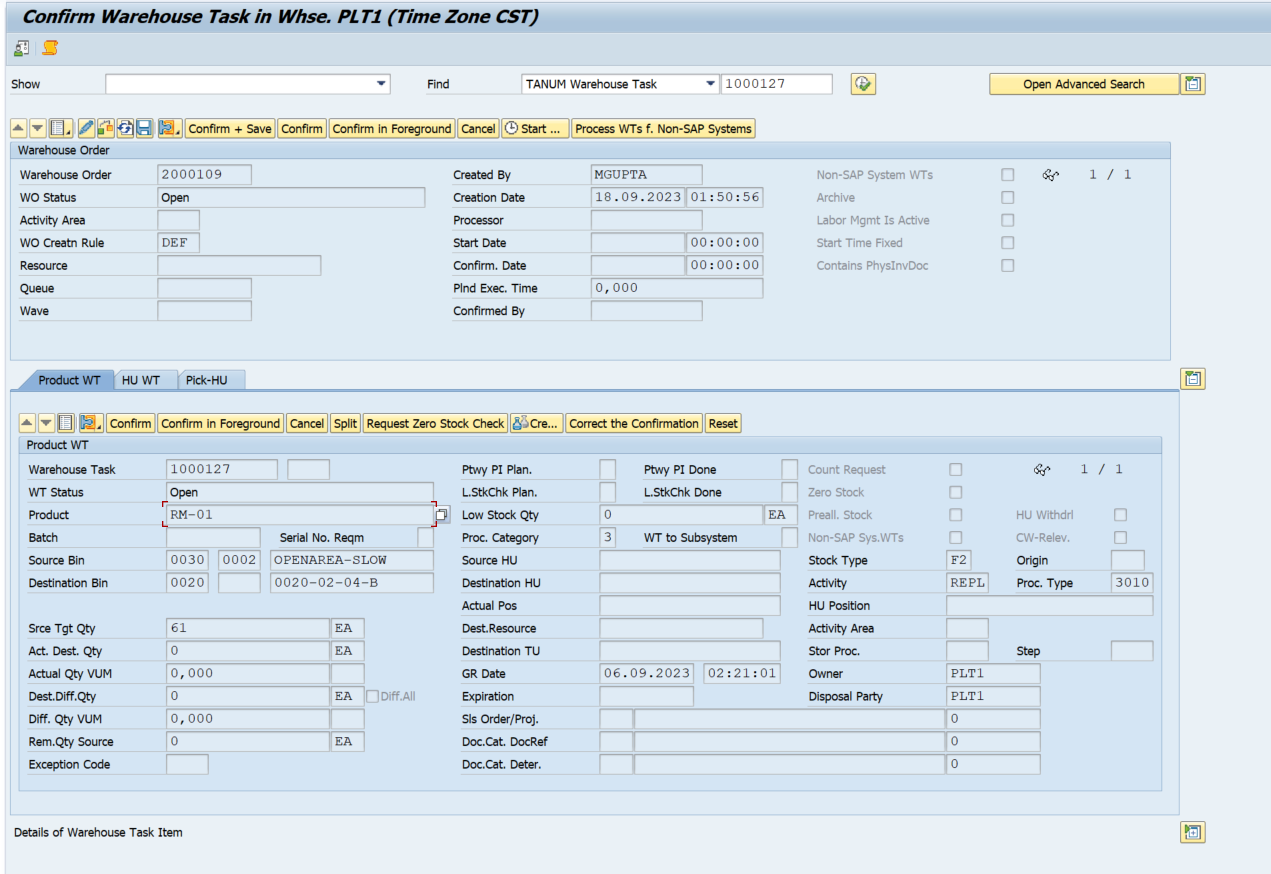

User TCode /SCWM/TO_CONF to confirm the WT