We will configure the STO process for 2 Plants under the same company code and perform the necessary steps to complete the STO process.

Define Shipping data for Plants

Assign Sales Org and Distribution Channel for Supplying plant

For receiving plant Assign Customer and sales org data

Assign Delivery type and checking rule

Assign Document type, One Step Procedure & Under delivery Tolerance

If we check the one-step option GR will be posted automatically in the receiving plant.

Assign shipping point to Supplying plant

Define Item Category Determination in Deliveries

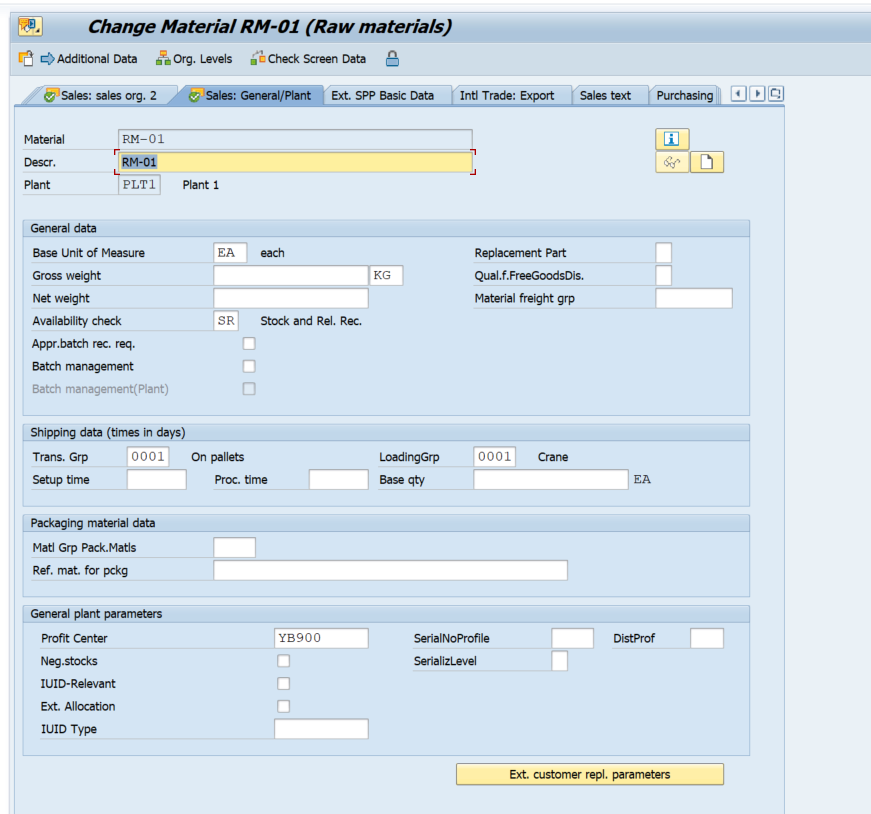

Maintain Sales Data in Material master for Supplying plant

Also, maintain the Vendor master for the Supplying plant, extend the material to the receiving plant, and maintain the plant/sloc data in the material master.

Now let us create an STO with doc type UB and also maintain the confirmation control key.

Run transaction VL10b to create the OBD for supplying plant

Now process the delivery in the EWM

We are getting an error while distributing the S4 delivery

Item 000010: No sales quantity is saved for item

Message no. SR053

Below Changes were made to resolve this issue.

Now we will process the OBD in EWM

Now we will check stock at IM and EWM level

Now we will confirm the WT

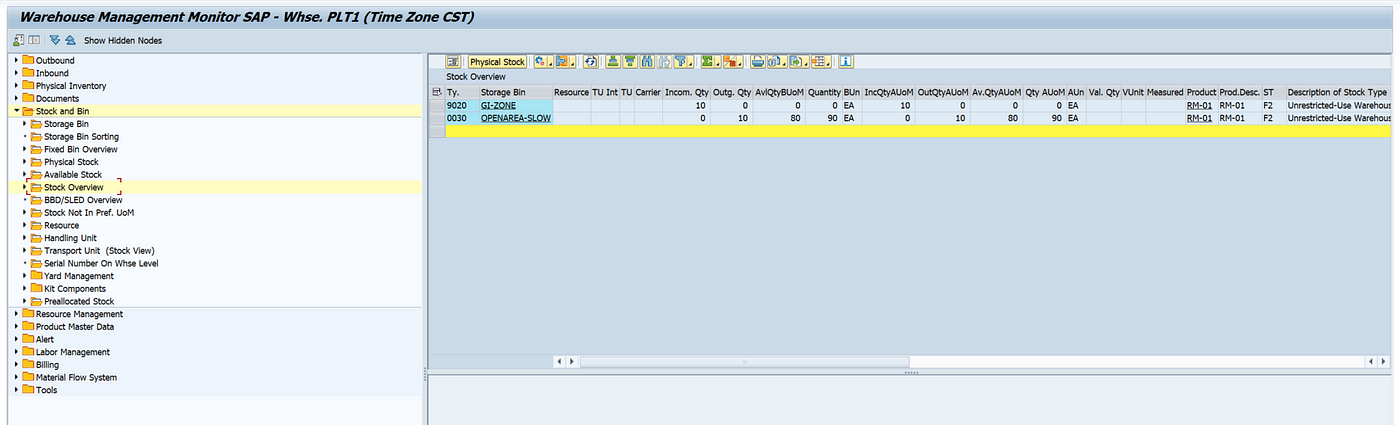

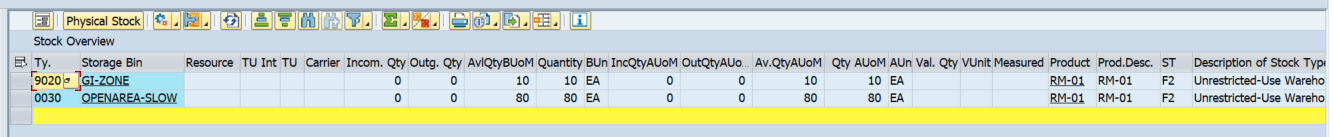

Now we will check the stock at EWM level

Once GI is done, the stock will get consumed from the 9020 interim storage type.

Now we will post GI

EWM Stock overview

S4 stock overview

OBD document flow in S4

Purchase order history of PO in S4

Now we can create INB for the receiving plant and post GR